Magnesium Oxide Foam Filter

Magnesium Oxide Foam Filter

Porosity: 80%-90%

Cell Size: 8–40 PPI

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

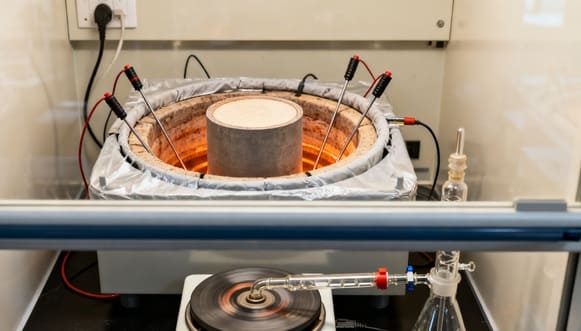

Magnesium Oxide Foam Filter offers a dependable solution for filtering molten magnesium alloys during casting. Its open-cell structure, formed through high-temperature sintering of magnesia-coated foam, ensures efficient removal of impurities and trapped gas. This leads to smoother metal flow, fewer casting flaws, and improved part consistency. Its strong chemical stability makes it suitable for use in demanding foundry environments. As a leading supplier and manufacturer of premium graphite products, Shanghai Yuepeng can supply high-quality magnesium oxide foam filters with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Magnesium Oxide Foam Filter Sheet

| Color: | Dark yellow |

| Chemical Formula: | MgO |

| Density: | 3.20 g/cm3 |

| Dimension: | customized |

| Shape: | Round, square, or customized |

| Pore Density (PPI): | 8–40 |

| Porosity (%): | 80–90 |

| Refractoriness (°C): | 1100 |

| Bending Strength (MPa): | 0.6 |

| Compression Strength (MPa): | 0.8 |

| Thermal Shock Resistance: | 6 times (1100°C to room temperature) |

| Applicable Alloys: | Nickel and high-activity alloys |

Magnesium Oxide Foam Filter Description

Magnesium oxide foam filter is a specialized filtration material designed for magnesium alloy casting. It is made by applying a magnesia-based slurry onto a polyurethane sponge and sintering it to form a rigid, porous ceramic structure. This filter effectively removes inclusions and traps gas during metal flow, enhancing casting purity and surface quality. Its excellent chemical compatibility with molten magnesium helps reduce reaction and contamination, making it a reliable choice for improving casting yield and reducing defects.

Magnesium Oxide Foam Filter Features

- Excellent filtration efficiency for magnesium alloys

- High porosity with uniform cell structure

- Chemically stable with molten magnesium

- Low thermal mass for fast heat transfer

- Lightweight and easy to handle during installation

Magnesium Oxide Foam Filter Applications

- Metal Casting Filtration: Magnesium oxide foam filters are primarily used in molten metal filtration, especially for aluminum, copper, and steel alloys. They effectively remove inclusions and impurities, improving casting quality and mechanical strength.

- Aerospace and Automotive Components: In high-performance sectors like aerospace and automotive manufacturing, MgO foam filters help achieve cleaner metal melts, leading to stronger and more reliable engine and structural parts.

- Foundry and Metallurgical Industry: These filters are widely used in foundries for refining molten metal streams, stabilizing flow, and reducing turbulence during pouring, ensuring smoother casting surfaces and fewer defects.

- High-Temperature Gas Purification: Magnesium oxide foam filters can also function in high-temperature gas purification systems, where their chemical stability and porosity allow efficient trapping of particulates and unwanted compounds.

- Energy and Power Generation: In power plants and renewable energy equipment manufacturing, MgO foam filters help maintain metal purity for turbine blades, heat exchangers, and other precision components requiring high thermal and structural reliability.

- Metal Casting

- Aerospace and Automotive

- Metallurgical Industry

- High-Temperature Laboratories

- Renewable Energy Systems

Magnesium Oxide Material Properties

Magnesium Oxide Ceramic Machining

Magnesium oxide can be machined in green or bisque form before sintering, and to a limited extent in its fully sintered state. In its pre-sintered state, the material is relatively soft and easier to shape, but like many ceramics, it undergoes significant shrinkage—up to 20%—during sintering, which can affect final dimensions. Fully sintered magnesium oxide is very hard and brittle, requiring diamond tools and precision equipment for any post-sintering machining.

Machining Methods and Considerations

- Green or Bisque Machining: Easier to cut and form, suitable for complex shapes before firing.

- Sintering Shrinkage: Expect about 15–20% dimensional reduction during sintering, which impacts tolerance control.

- Post-Sintering Machining: Requires diamond grinding tools due to the material’s hardness and brittleness.

- Fragility: Fully sintered MgO is prone to chipping and fracture if not handled with care during machining.

- Tooling and Time: Machining dense MgO ceramics is time-consuming and requires specialized equipment.

Magnesium Oxide Ceramic Packaging

Magnesium Oxide Ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of the products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.