Magnesia Foam

Magnesia Foam

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

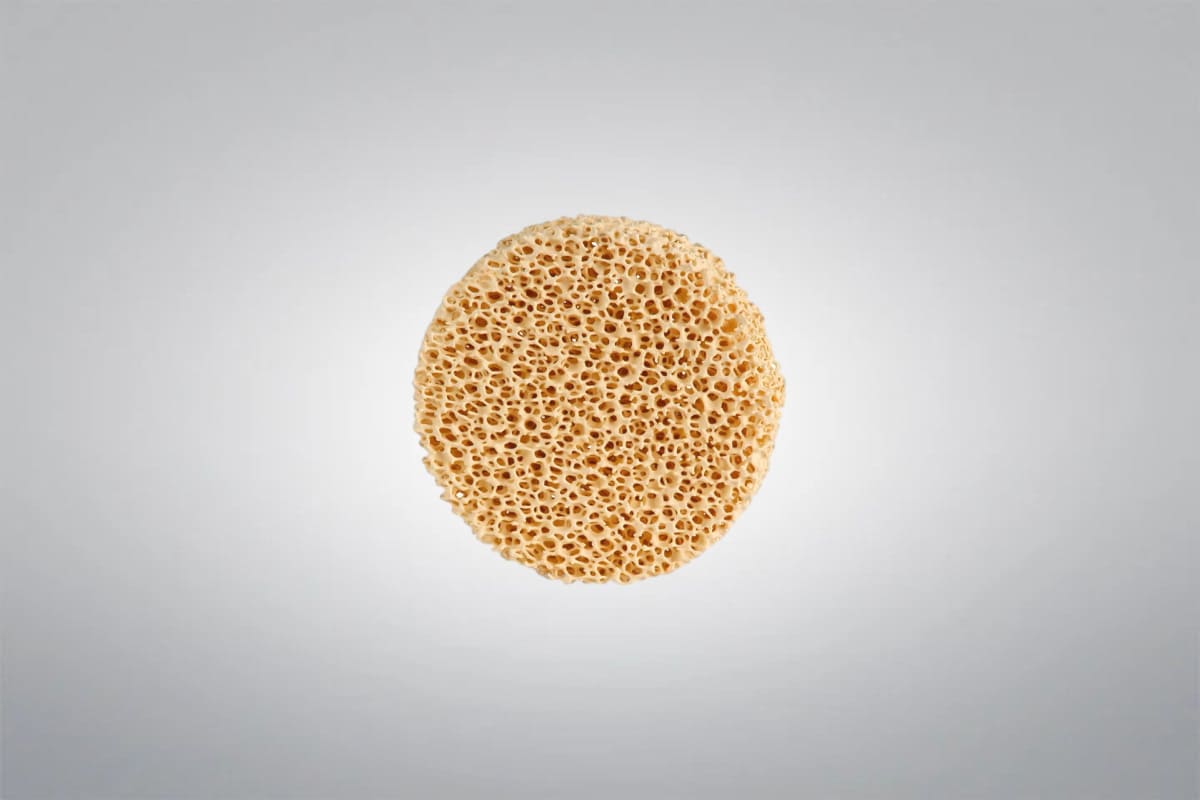

Magnesia Foam is a lightweight, porous ceramic material made from high-purity magnesium oxide. It offers excellent thermal insulation, corrosion resistance, and compatibility with molten magnesium alloys. Widely used in filtration, thermal shielding, and high-temperature applications, it helps improve casting quality while maintaining structural stability. As a leading supplier and manufacturer of premium graphite products, Shanghai Yuepeng can supply high-quality magnesia foam with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Magnesia Foam Data Sheet

| Shape: | Round, Square |

| Pore Density (PPI): | 8–40 |

| Chemical formula: | MgO |

| Porosity (%): | 80–90 |

| Refractoriness (°C): | 1100 |

| Bending Strength (MPa): | 0.6 |

| Compression Strength (MPa): | 0.8 |

| Thermal Shock Resistance: | 6 times (1100°C to room temperature) |

| Applicable Alloys: | Nickel and high-activity alloys |

Magnesia Foam Description

Magnesia Foam is a porous ceramic material engineered from high-purity magnesium oxide, offering excellent thermal resistance, chemical stability, and filtration performance. Manufactured using a replica technique that involves coating a polymer template with a magnesia slurry, followed by burnout and high-temperature sintering, this foam features a uniform pore structure and high open porosity. It is especially suited for high-temperature filtration in magnesium alloy processing and other non-ferrous metal applications. The structure enables efficient removal of inclusions while maintaining minimal flow resistance, enhancing both metal cleanliness and final product reliability.

Magnesia Foam Advantages

- Excellent Thermal Stability: Maintains structural integrity at high temperatures, making it ideal for molten metal filtration.

- High Chemical Resistance: Inert to magnesium and its alloys, reducing contamination during casting.

- Efficient Filtration Performance: Effectively traps slag and inclusions, enhancing the quality of cast components.

- Lightweight and Porous Structure: Ensures low thermal mass and fast heat-up rates, improving energy efficiency.

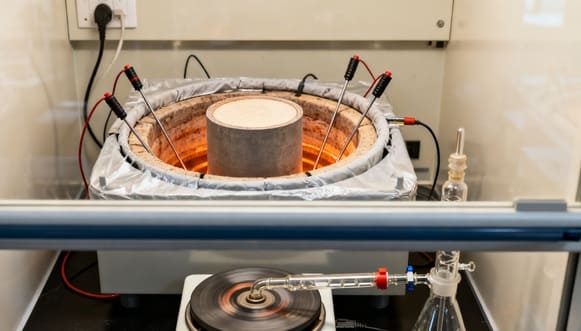

- Environmentally Friendly Production: Uses water-based binders and energy-saving kilns to reduce emissions and costs.

Magnesia Foam Applications

- Molten Metal Filtration: Magnesia foam is widely used as a filter material in casting processes to remove impurities and inclusions from molten metals, improving the purity and quality of final products.

- High-Temperature Insulation: It serves as an effective thermal insulator in furnaces and kilns, maintaining temperature stability and reducing heat loss during high-temperature operations.

- Catalyst Supports: Magnesia foam is used as a support material for catalysts in chemical reactions, providing a large surface area and excellent thermal resistance.

- Gas and Fluid Purification: Due to its porous structure, magnesia foam is applied in filtration systems for gas purification, absorbing harmful substances, and improving environmental performance.

- Biomedical and Research Fields: It is used in experimental and biomedical applications where high porosity and biocompatibility are required, such as in bone tissue engineering and material studies.

- High-Temperature Laboratories

- Catalyst Support

- Material research

- Molten Metal Filtration

Magnesium Oxide Material Properties

Magnesium Oxide Ceramic Machining

Magnesium oxide can be machined in green or bisque form before sintering, and to a limited extent in its fully sintered state. In its pre-sintered state, the material is relatively soft and easier to shape, but like many ceramics, it undergoes significant shrinkage—up to 20%—during sintering, which can affect final dimensions. Fully sintered magnesium oxide is very hard and brittle, requiring diamond tools and precision equipment for any post-sintering machining.

Machining Methods and Considerations

- Green or Bisque Machining: Easier to cut and form, suitable for complex shapes before firing.

- Sintering Shrinkage: Expect about 15–20% dimensional reduction during sintering, which impacts tolerance control.

- Post-Sintering Machining: Requires diamond grinding tools due to the material’s hardness and brittleness.

- Fragility: Fully sintered MgO is prone to chipping and fracture if not handled with care during machining.

- Tooling and Time: Machining dense MgO ceramics is time-consuming and requires specialized equipment.

Magnesium Oxide Ceramic Packaging

Magnesium Oxide Ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of the products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.