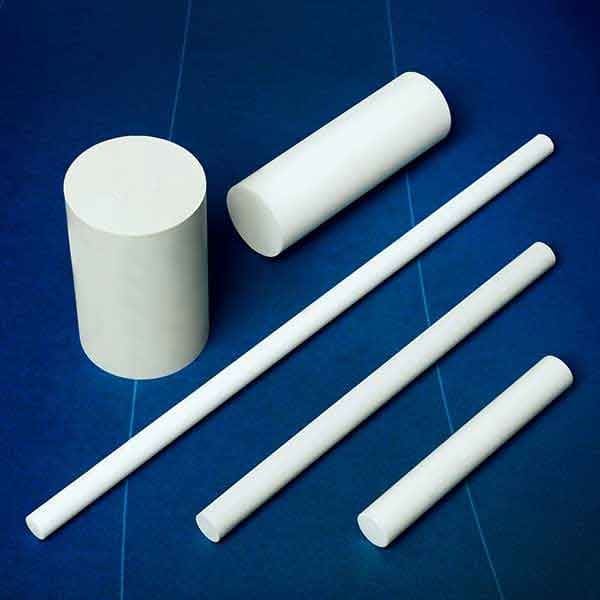

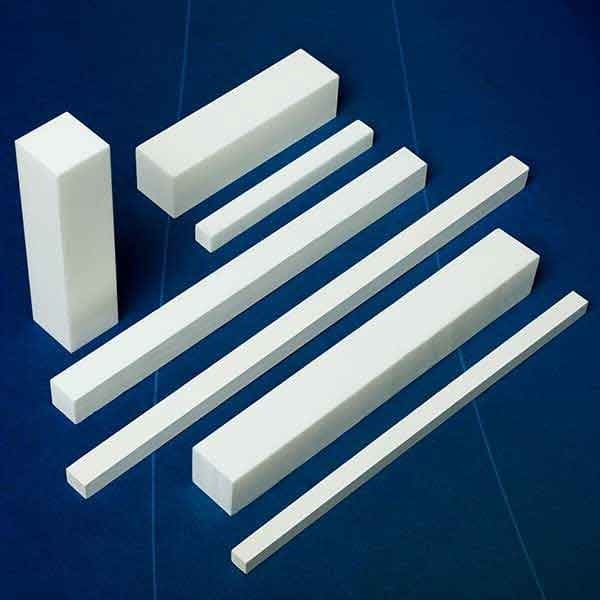

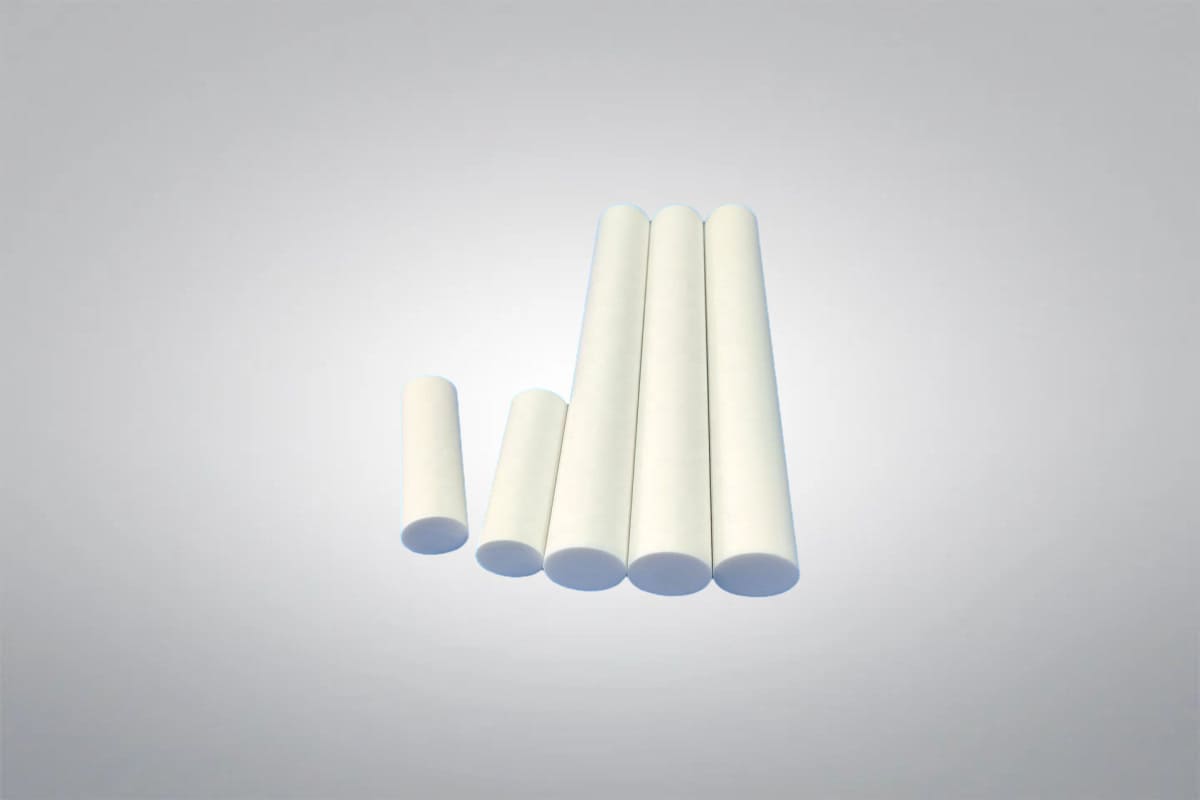

Macor Rod/Bar

Macor Rod/Bar

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

Macor Rod/Bar offers the same outstanding properties as Macor plates, including high-temperature resistance up to 800°C, electrical insulation, and excellent dimensional stability. These rods and bars can be easily machined into precise shapes using standard metalworking tools, without the need for sintering or molds. This makes them ideal for rapid prototyping and small-scale production of components used in aerospace, analytical instruments, semiconductor fixtures, and high-vacuum environments. As a leading supplier and manufacturer of premium macor machinable glass ceramic products, Shanghai Yuepeng can supply high-quality macor rod/bar with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Macor Rod/Bar Data Sheet

| Color: | White |

| Material Composition: | Fluorphlogopite & Borosilicate Glass |

| Dimensions: | Customized |

| Processing Precision: | 0.01mm |

| Roughness: | 0.8μm |

Macor Rod/Bar Description

Macor Rod/Bar offers a reliable combination of high mechanical strength, electrical insulation, and excellent dimensional stability across extreme temperatures. With zero porosity and the ability to withstand up to 800°C under load (and 1000°C without load), it maintains rigidity where many high-temperature plastics would deform. It can be machined with standard metalworking tools to very tight tolerances, eliminating the need for post-machining sintering. Macor rods are also vacuum-compatible, non-outgassing, and can be bonded or metallized, making them a practical solution for demanding applications in aerospace, medical, and high-precision instrumentation.

Macor Rod Macor Bar

Macor Rod/Bar Chemical Compositions

| Element / Compound | Approximate Weight (%) |

|---|---|

| Silicon (SiO₂) | 46% |

| Magnesium (MgO) | 17% |

| Aluminum (Al₂O₃) | 16% |

| Potassium (K₂O) | 10% |

| Boron (B₂O₃) | 7% |

| Fluorine (F) | 4% |

Macor Rod/Bar Features

- Easily Machinable with Metal Tools: No need for sintering or special equipment—Macor can be drilled, milled, and turned using standard metalworking tools.

- High Thermal Resistance: Maintains strength and shape up to 800°C (and even 1000°C without load), making it reliable for extreme heat environments.

- Excellent Electrical Insulation: Withstands high voltages and offers stable dielectric performance, suitable for vacuum and electronic applications.

- Zero Porosity and Low Outgassing: Ideal for ultra-clean systems such as semiconductor chambers, space applications, and medical environments.

- Dimensional Stability: Low thermal expansion and good thermal shock resistance ensure components remain precise even under fluctuating temperatures.

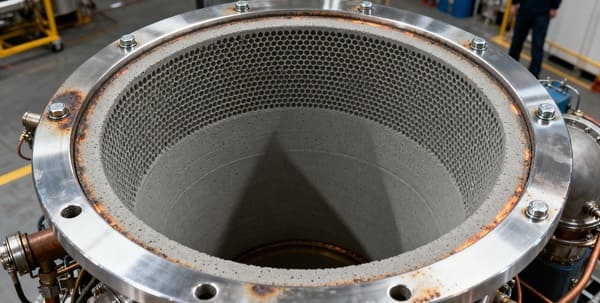

Macor Rod/Bar Applications

- High-Temperature Insulation: Macor rods and bars are used as electrical and thermal insulators in environments that demand stability up to 1000°C, such as in furnace fixtures and heating systems.

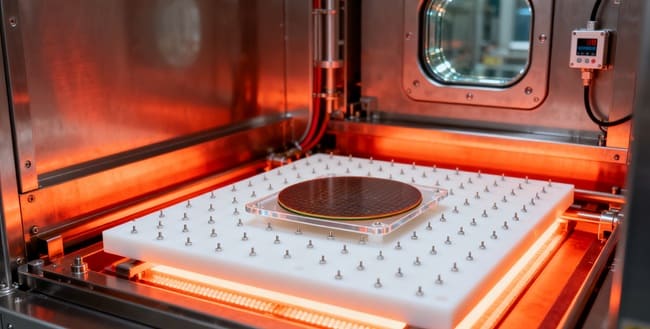

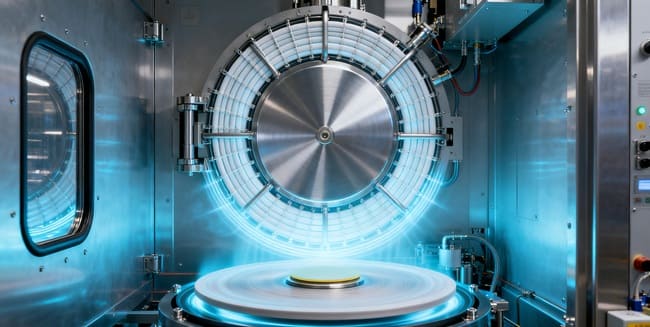

- Semiconductor Processing: They are applied in wafer handling tools, plasma etching systems, and vacuum chambers where high purity and low outgassing are essential.

- Aerospace Components: Macor rods and bars serve as structural supports and insulating parts in aerospace instruments due to their machinability and thermal endurance.

- Medical and Analytical Equipment: They are used in imaging devices, sensors, and diagnostic instruments that require precise and contamination-free ceramic materials.

- Optical and Laser Systems: Macor rods and bars are applied in optical mounts, laser housings, and alignment fixtures where low thermal expansion and high dimensional stability are needed.

- High-Temperature Insulating Parts

- Semiconductor Processing

- Optical and electronic industries

- Aerospace Components

- Medical Devices

Macor Machinable Glass Ceramic Properties

Macor Machinable Glass Ceramic Material Machining

Macor is one of the rare ceramics that can be machined using standard metalworking tools without the need for post-sintering processes. This makes it especially useful for prototyping and custom part production with tight tolerances. However, understanding its machining behavior is key to achieving clean, precise results.

- Standard Tool Compatibility: Macor can be drilled, milled, turned, and tapped using regular carbide or high-speed steel tools, eliminating the need for diamond tooling.

- No Plastic Deformation: Unlike metals or plastics, Macor does not deform before breaking. Operators must prevent stress concentrations to avoid edge chipping or cracking.

- Machining Precision: Surface finishes up to 0.5 µm and tolerances as tight as ±0.005 mm are achievable with careful planning and skilled handling.

- Dry Machining Preferred: Coolants are generally not required. Dry machining helps prevent contamination and simplifies cleanup in high-purity applications.

- Practice Recommended: Due to Macor’s unique cutting behavior, it’s recommended to practice machining techniques on scrap material before processing final components.

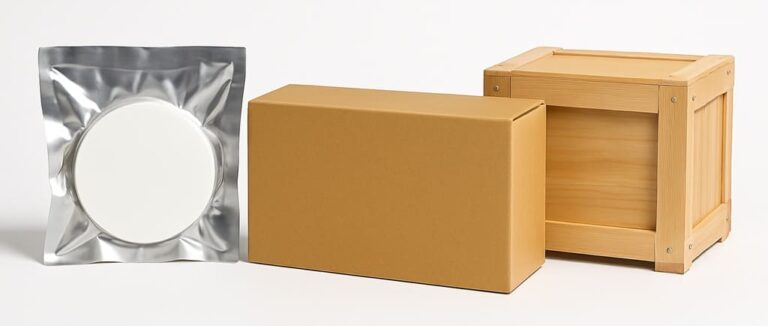

Macor Machinable Glass Ceramic Packaging

Macor machinable glass ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of the products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.