Beryllium Oxide Rod

Beryllium Oxide Rod

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

Beryllium Oxide Rod is a high-performance ceramic component featuring exceptional thermal conductivity, excellent electrical insulation, and strong mechanical properties. It is ideal for use in high-power electronics, vacuum systems, and thermal management applications where efficient heat transfer and electrical isolation are critical. The rod’s ability to withstand high temperatures and thermal shock makes it suitable for demanding environments across aerospace, medical, and industrial sectors. As a leading supplier and manufacturer of premium beryllium oxide products, Shanghai Yuepeng can supply high-quality Beryllium Oxide Rod with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Beryllium Oxide Rod Data Sheet

| Color: | White |

| Chemical Formula: | BeO |

| Dimension: | customized |

| Machining Accuracy: | 0.01 mm |

| Surface Roughness: | 0.1 μm |

Beryllium Oxide Rod Description

Beryllium Oxide Rod is a precision-engineered ceramic element designed for applications that demand both high thermal efficiency and electrical resistance. Its unique combination of low dielectric loss and high heat conductivity makes it a preferred choice in RF devices, microwave systems, and advanced sensor assemblies. The rod maintains excellent dimensional stability under extreme thermal conditions, offering long-term reliability in both continuous and pulsed high-temperature operations. Its non-reactive nature also supports use in chemically aggressive or vacuum environments.

Beryllium Oxide Rod Chemical Compositions

| Element | Content (ppm) |

|---|---|

| Boron (B) | 2 |

| Aluminum (Al) | 46 |

| Chromium (Cr) | 8 |

| Iron (Fe) | 32 |

| Magnesium (Mg) | 1000 |

| Manganese (Mn) | 2 |

| Nickel (Ni) | 9 |

| Titanium (Ti) | 5 |

| Sodium (Na) | 173 |

| Calcium (Ca) | 31 |

| Silicon (Si) | 2100 |

Beryllium Oxide Rod Features

- High Thermal Conductivity: Efficiently transfers heat, making it ideal for heat-sensitive applications.

- Excellent Electrical Insulation: Prevents current leakage in high-voltage and high-frequency systems.

- Strong Mechanical Stability: Maintains structural integrity under mechanical stress and thermal cycling.

- Chemical Inertness: Resistant to most chemicals, suitable for harsh or reactive environments.

- Low Dielectric Loss: Performs well in RF and microwave applications with minimal signal loss.

Beryllium Oxide Rod Applications

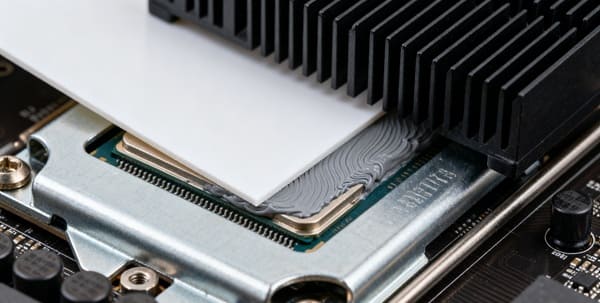

- Electronic Insulators: Beryllium oxide rods are commonly used as insulating supports in high-power electronic circuits and vacuum tubes, combining electrical insulation with exceptional heat dissipation.

- Thermal Management Systems: Due to their high thermal conductivity, BeO rods serve as heat spreaders or conductors in systems that require efficient temperature control and minimal thermal expansion.

- Semiconductor Equipment: They are applied in semiconductor processing tools where both purity and resistance to high-temperature corrosion are critical for maintaining clean manufacturing conditions.

- Aerospace and Defense Applications: Beryllium oxide rods are used in aerospace systems and defense electronics that demand stable performance under extreme thermal and mechanical stress.

- Scientific and Medical Devices: In advanced laboratory and medical instruments, BeO rods provide both electrical insulation and precise thermal control for reliable and consistent performance.

- Medical Devices

- Optoelectronic Device Fabrication

- Thermal Management Materials

- Semiconductor Equipment

- Defense and Aerospace

Beryllium Oxide Ceramic Properties

Beryllium Oxide Ceramic Material Machining

Beryllium Oxide (BeO) Ceramic is valued for its exceptional thermal conductivity, electrical insulation, and high melting point. These qualities make it widely used in electronics and high-temperature applications, but its hardness and brittleness require special machining approaches. Key machining considerations include:

- Cutting: Precision diamond-coated tools or laser cutting are essential to avoid microcracks and maintain clean edges, as BeO’s brittleness can lead to chipping during conventional cutting.

- Grinding: Fine diamond grinding wheels enable accurate shaping and surface finishing while minimizing the risk of fractures, especially important for small or complex parts.

- Drilling: Ultrasonic machining or abrasive waterjet methods are preferred to produce precise holes without causing thermal damage or cracks.

- Surface Finishing: Polishing techniques enhance surface smoothness and electrical insulation properties, crucial for applications demanding high dielectric performance and reliability.

Beryllium Oxide Ceramic Packaging

Beryllium Oxide Ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of the products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.