Alumina Powder

Alumina Powder

Purity: 99.9%-99.999%

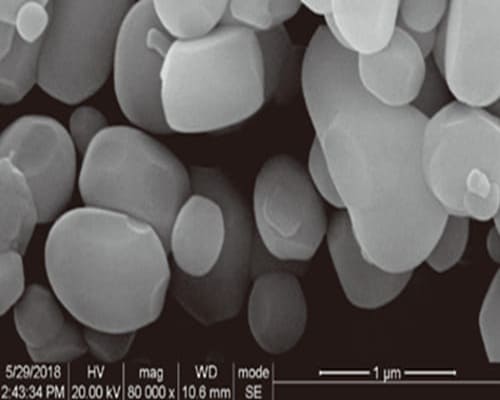

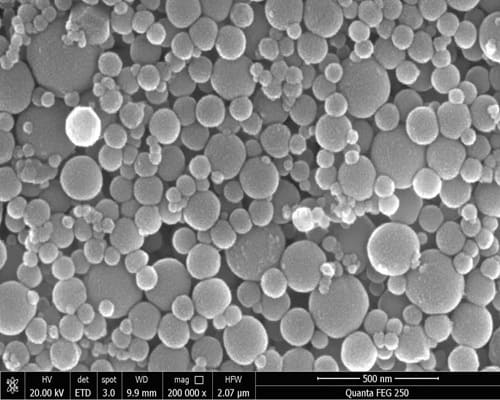

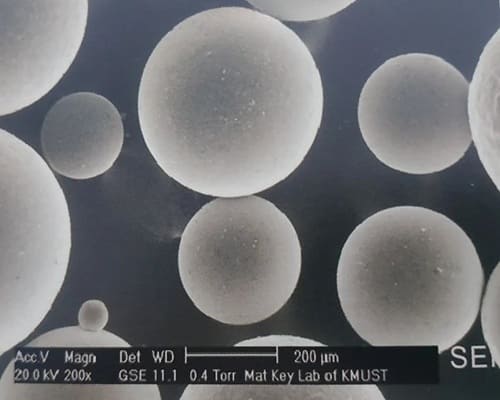

Morphology: Near-spherical, Spherical, or Irregular

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

Alumina Powder is primarily made from high-purity aluminum oxide (Al2O3), offering strong heat resistance, good formability, stable crystal phase, high hardness, and excellent dimensional stability. As a leading supplier and manufacturer of premium alumina products, Shanghai Yuepeng utilizes advanced machining centers to produce high-quality alumina powder for a wide range of applications.

Alumina Powder Data Sheet

| Reference Code: | HM1970 |

| Purity: | 99.9%-99.999% |

| Morphology: | Near-spherical, Spherical, or Irregular |

| Appearance: | White Powder |

| Particle Size: | Sub-micron to 500 micron, or Nano-scale |

Alumina Powder Description

Alumina Powder is a white powder with a purity of 99.9% to 99.999%. High-purity alumina powders are ideal for growing sapphires, lithium-ion batteries, LED substrates, specialty ceramics, and industrial catalysts. They can also be used in polishing, thermal management, and catalysts. Depending on specific application requirements, the particle size, purity, and morphology can be customized. Shanghai Yuepeng can supply high-quality alumina powder in the form of near-spherical, spherical, irregular, and nano-scale particles to meet diverse industrial and research requirements.

Alumina Powder Fine Particle Solutions

Spherical Powder

Spherical Alumina Powder is a high-performance Al2O3 material with perfectly spherical particles, high thermal conductivity, and low surface roughness. The products include the HMBAK series, HM Top Cut series, HMBAH series, and HMBAM series.

Alumina Powder Advantages

- High Purity: Provides high-purity alumina particles, ensuring stability and performance in applications.

- Excellent Thermal Stability: Maintains stable physical and chemical properties in high-temperature environments.

- Good Flowability: The granulated alumina powder exhibits excellent flowability, facilitating automated production and precise batching.

- High Hardness and Wear Resistance: Exhibits high hardness and excellent wear resistance, making it suitable for applications with high wear resistance requirements.

Alumina Powder Applications

- Ceramics Manufacturing: It is widely used in producing advanced ceramics such as spark plugs, cutting tools, substrates, and wear-resistant parts due to its high hardness and thermal stability.

- Electronics: It serves as an insulating material in electronic components like IC substrates, circuit boards, and capacitor dielectrics, benefiting from its excellent electrical insulation properties.

- Polishing and Abrasives: Owing to its high hardness, alumina powder is applied in precision polishing of optical lenses, semiconductors, and metals, as well as in grinding wheels and abrasive papers.

- Catalyst and Catalyst Carrier: function as a catalyst or a support material in petrochemical reactions, especially in catalytic cracking, hydrogenation, and environmental purification processes.

- Refractories: It is a core raw material for producing refractory bricks, coatings, and linings in high-temperature furnaces, kilns, and reactors, thanks to its superior thermal resistance.

- Ceramic Additives

- Polishing and Coating

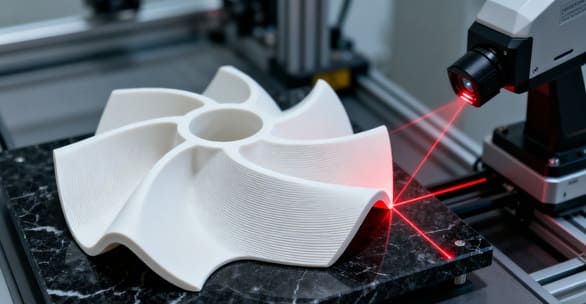

- Additive Manufacturing and Coatings

- Catalyst Supports

- Refractories

Alumina Powder Packaging

The Alumina Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.