Aluminum Nitride Powder

Aluminum Nitride Powder

Purity: 99%-99.9%

Particle Size: 1.0-2.0 μm, or customized

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

Aluminum Nitride Powder is a high-performance ceramic material with excellent thermal conductivity and electrical insulation properties. It is commonly used to manufacture high-performance ceramic components, integrated circuit substrates, electronic devices, optical components, heat sinks, high-temperature crucibles, etc. As a leading supplier and manufacturer of premium alumina products, Shanghai Yuepeng can supply high-quality aluminum nitride powders with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Aluminum Nitride Powder Data Sheet

| Reference Code: | HMNP-1679 |

| Purity: | 99%-99.9% |

| Particle Size: | 1.0-2.0 μm, or customized |

| CAS: | 24304-00-5 |

| Melting Point: | 2200℃ |

| Boiling Point: | 2249℃ |

| Moh’s Hardness: | 9-10 |

| Refractive Index: | 1.9-2.2 |

Aluminum Nitride Powder Description

Aluminum Nitride Powder is characterized by high purity, low impurity content, and high sintering activity. Its unique structure offers excellent stability and corrosion resistance at high temperatures. Aluminum nitride powder is ideal for producing thermal interface materials, LED heat sinks, and electronic packaging, and it is compatible with advanced manufacturing processes such as dry pressing and isostatic pressing. We can supply a series of aluminum nitride powder to meet diverse applications, including AlN spherical powder, AlN granulation powder, and AlN surface modification powder. Shanghai Yuepeng can provide customized solutions in purity and particle size to meet various industrial and research applications.

Aluminum Nitride Powder Specifications

| Item | Unit | Value |

| Carbon (C) | ppm | <400 |

| Oxygen (O) | % | <0.85 |

| Specific Surface Area | m2/g | 2.0~2.4 |

| D50 | μm | 1.3~1.8 |

| Calcium (Ca) | ppm | <250 |

| Silicon (Si) | ppm | <15 |

| Iron (Fe) | ppm | <15 |

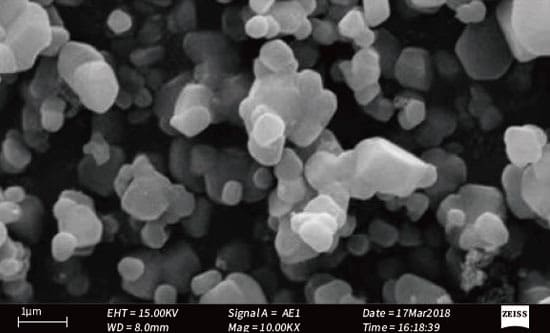

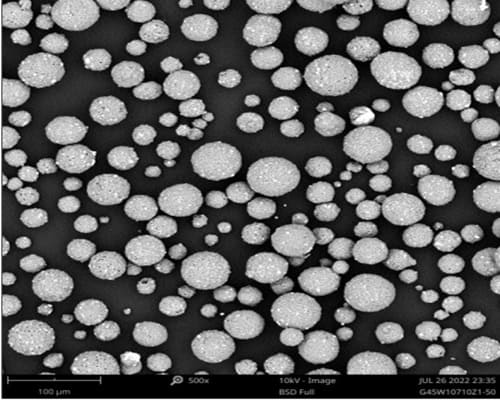

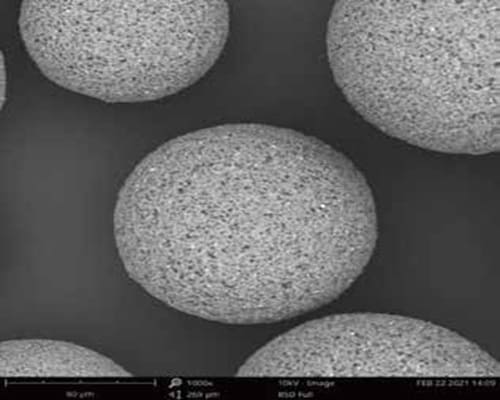

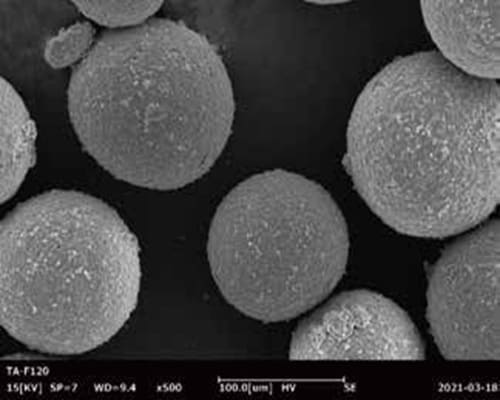

Aluminum Nitride Powder SEM

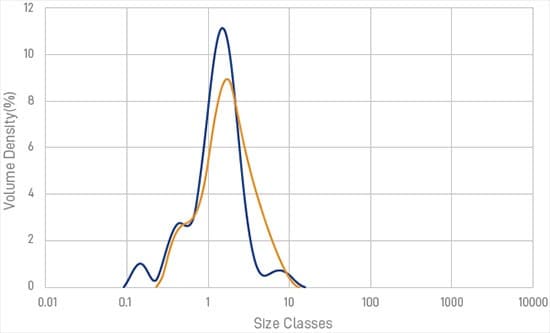

Aluminum Nitride Powder Particle Size Distribution

Aluminum Nitride Powder Solutions

Spherical Powder

Aluminum Nitride (AlN) Spherical Powder, made by spray granulation, sintering, and classification, offers high thermal conductivity, purity, sphericity, and good flowability. It’s widely used as a thermal interface material.

Granulation Powder

Aluminum Nitride Granulation Powder, with excellent formability and flowability, is ideal for dry pressing, semi-dry pressing, and cold isostatic pressing, used in electrostatic chucks and ceramic components.

Surface Modification Powder

Aluminum nitride surface modification powder addresses issues like poor stability and water hydrolysis at room temperature, producing a hydrophobic modified aluminum nitride product through a tailored modification process.

Aluminum Nitride Powder Applications

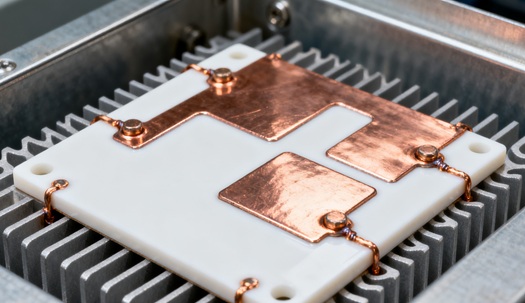

- Electronic Substrates: Used to manufacture high thermal conductivity and electrically insulating substrates for semiconductors and microelectronics.

- Heat Dissipation Materials: Incorporated into heat sinks, thermal interface materials, and packaging to improve device cooling and reliability.

- Ceramic Components: Serves as a raw material for advanced ceramics with excellent mechanical strength and resistance to thermal shock.

- Polymer and Resin Composites: Added to polymers to enhance thermal conductivity while maintaining electrical insulation for electronics and automotive uses.

- Protective Coatings: Applied in coatings to provide oxidation resistance, thermal stability, and durability under harsh industrial conditions.

- Ceramic Reinforcement

- Coating Additives

- Metal Surface Treatment

- Polymer Modification

- Power Electronics

Aluminum Nitride Powder Packaging

The Aluminum Nitride Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.