Aluminum Nitride Surface Modification Powder

Aluminum Nitride Surface Modification Powder

Purity: 99%-99.9%

Particle Size: 30-120 μm, or customized

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

Aluminum Nitride Surface Modification Powder is a hydrophobic modified aluminum nitride product customized through a modification process. As a leading supplier and manufacturer of premium alumina products, Shanghai Yuepeng can supply high-quality aluminum nitride surface modification powders with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Aluminum Nitride Surface Modification Powder Data Sheet

| Reference Code: | HM1911 |

| Purity: | 99%-99.9% |

| Particle Size: | 30-120 μm or customized |

| CAS: | 24304-00-5 |

| Melting Point: | 2200℃ |

| Boiling Point: | 2249℃ |

Aluminum Nitride Surface Modification Powder Description

Aluminum Nitride Powder has poor stability and can be hydrolyzed in water at ambient temperature, resulting in a decrease in the thermal conductivity of the powder. We offer a range of modified aluminum nitride powders tailored to various applications. Choose the right modification based on your needs: silane modification for better resin compatibility or hydrolysis-resistant treatment for improved moisture resistance.

Aluminum Nitride Surface Modification Powder Specifications

| Item | HM-F1T08 | HM-F120T01 | |

| D50 (μm) | 1.41 | 121.6 | |

| Specific area (m2/g) | 1.28 | 0.01 | |

| Impurity Content | O (%) | 0.93 | 1.41 |

| Ca (ppm) | <300 | <300 | |

| Fe (ppm) | <25 | <50 | |

| Si (ppm) | <20 | <30 | |

| Apparent density (g/cm3) | 1.05 | 1.81 | |

| Tap density (g/cm3) | 1.64 | 2.04 | |

| Moisture (%) | 0.02 | 0.02 | |

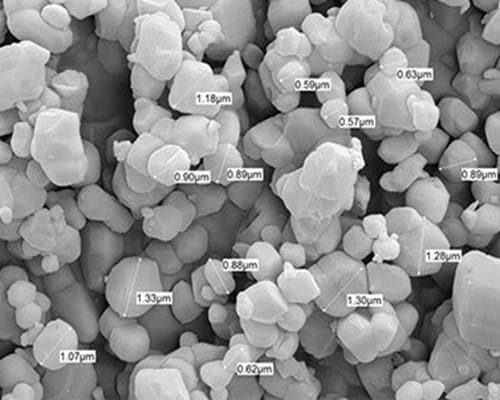

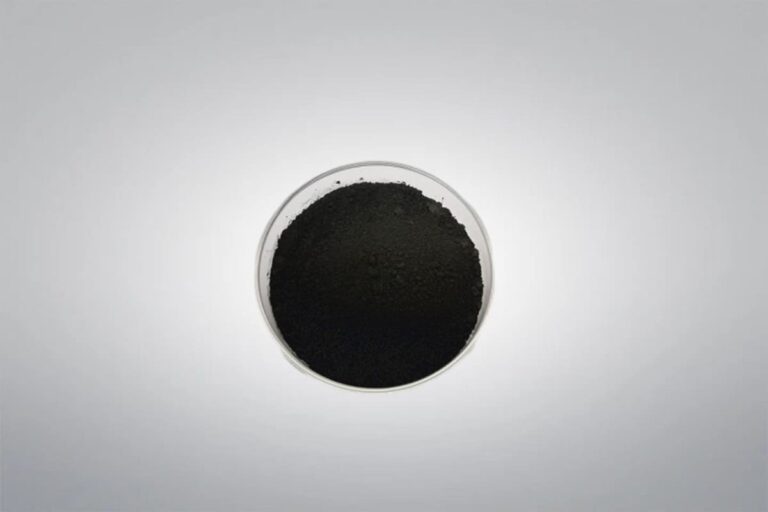

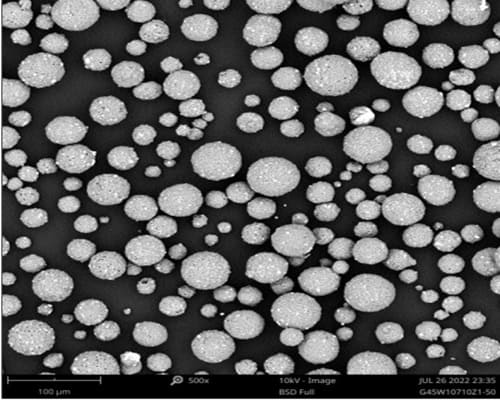

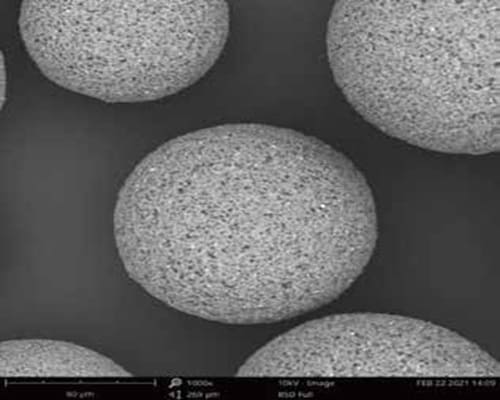

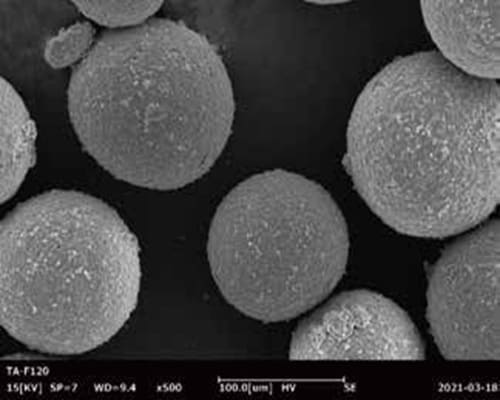

Aluminum Nitride Surface Modification Powder Morphology

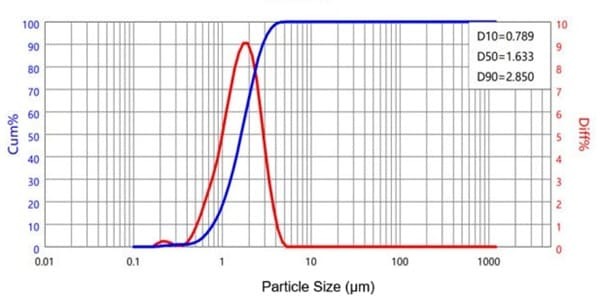

Aluminum Nitride Surface Modification Powder Particle Size Distribution

Aluminum Nitride Surface Modification Powder Features

- High thermal conductivity

- Strong hydrolysis resistance

- Excellent hydrophobicity

- Narrow particle size distribution

Aluminum Nitride Powder Surface Modification Solutions

Tailor your aluminum nitride powder with specialized surface treatments to achieve optimal performance:

- Silane Coupling Agent Modification: Improves dispersion and bonding in polymer matrices (e.g., epoxy, silicone) for superior composite performance.

- Inorganic Hydrolysis Resistant Treatment: Provides long-term stability in humid or aqueous environments by preventing moisture degradation.

- Dual Modification (Silane + Hydrolysis Resistance): Combines enhanced resin compatibility with environmental protection for demanding applications.

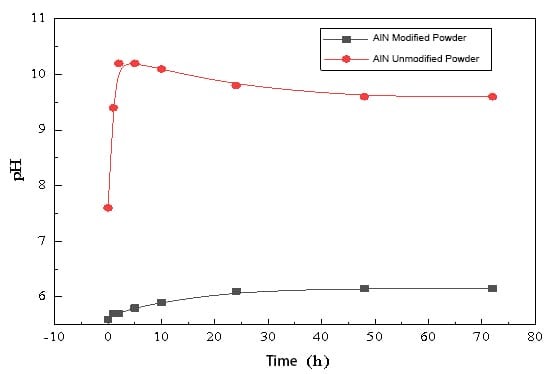

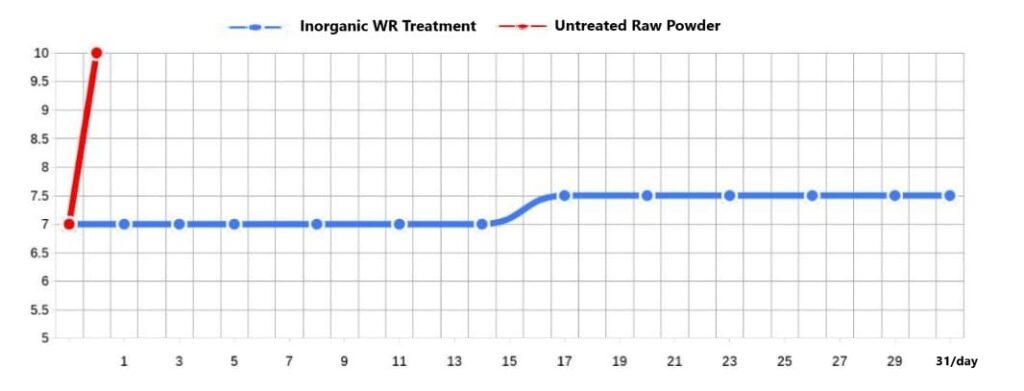

Aluminum Nitride Surface Modification Powder Hydrolysis Testing

The unmodified AIN undergoes almost complete hydrolysis after 2 hours at 70°C, resulting in a strong, irritating ammonia odor and significant clumping at the bottom of the cup. In contrast, our modified product shows no ammonia odor and no clumping even after 72 hours of hydrolysis, with almost no signs of hydrolysis.

- Experimental Conditions: 30g of Aluminum Nitride, 300g of pure water, water temperature at 70°C.

- Experimental Method: The degree of hydrolysis is determined by observing the experimental phenomena and measuring the pH value of the solution.

| Time (h) | 0 | 1.0 | 2.0 | 5.0 | 10.0 | 24.0 | 48.0 | 72.0 |

| AlN Modified Powder (pH) | 5.6 | 5.7 | 5.7 | 5.8 | 5.9 | 6.1 | 6.15 | 6.15 |

| AlN Unmodified Powder (pH) | 7.6 | 9.4 | 10.2 | 10.2 | 10.1 | 9.8 | 9.6 | 9.6 |

AlN Powder with Inorganic Hydrolysis-Resistant Modification

AlN is widely used in electronics for its high thermal conductivity (320 W/(m·K)), but it reacts with water after moisture absorption, reducing its thermal performance. Surface treatment with coupling agents can lower its hydrolysis, but limits further treatment. Shanghai Yuepeng’s inorganic coating method overcomes this, allowing further organic coatings and providing better stability for high-reliability applications.

| Product Name | Aluminum Nitride Filler Powder WR Type | ||

| Equipment and Materials | Thermostatic water bath, beaker, pure water, wide-range pH test paper | ||

| Test Procedure | 1. Set the water bath to 80°C. 2. Weigh 10g of sample into a 250ml beaker, add pure water to the 100ml mark. 3. Place the beaker in a water bath, monitor pH changes (add pure water as needed). | ||

| Test Results (L/LG Grade) | 7 days | 14 days | 30 days |

| pH = 7 | pH ≤ 7.5 | pH ≤ 8.5 | |

| Test Results (G Grade) | 7 days | 14 days | 30 days |

| pH = 7 | pH ≤ 7 | pH ≤ 7.5 | |

| Remarks | Ordinary AlN powder: pH >10 in 15 mins, ammonia odor, clumping. WR-coated powder: pH < 8.5 after 30 days, no ammonia odor, no clumping. | ||

Aluminum Nitride Powder Solutions

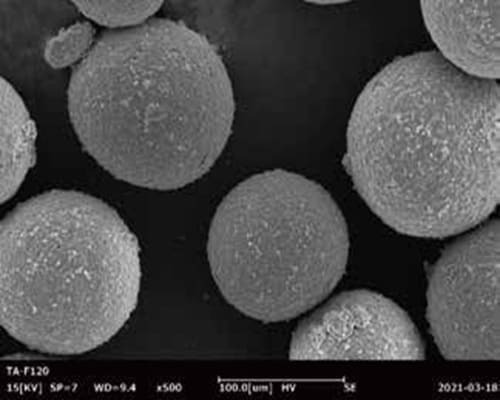

Spherical Powder

Aluminum Nitride (AlN) Spherical Powder, made by spray granulation, sintering, and classification, offers high thermal conductivity, purity, sphericity, and good flowability. It’s widely used as a thermal interface material.

Granulation Powder

Aluminum Nitride Granulation Powder, with excellent formability and flowability, is ideal for dry pressing, semi-dry pressing, and cold isostatic pressing, used in electrostatic chucks and ceramic components.

Surface Modification Powder

Aluminum nitride surface modification powder addresses issues like poor stability and water hydrolysis at room temperature, producing a hydrophobic modified aluminum nitride product through a tailored modification process.

Aluminum Nitride Surface Modification Powder Applications

- Polymer Modification: Improves the thermal conductivity and mechanical strength of polymer composites while maintaining electrical insulation.

- Metal Surface Treatment: Enhances wear resistance, oxidation resistance, and thermal stability of metal parts in demanding environments.

- Ceramic Reinforcement: Strengthens ceramic matrices by improving toughness, thermal conductivity, and resistance to thermal shock.

- Electronic Packaging: Applied to semiconductor and microelectronic devices to improve heat dissipation and reliability.

- Coating Additives: Used in coatings to increase thermal management, corrosion resistance, and durability for aerospace, automotive, and industrial applications.

- Ceramic Reinforcement

- Coating Additives

- Metal Surface Treatment

- Polymer Modification

- Electronic packaging materials

Aluminum Nitride Surface Modification Powder Packaging

The Aluminum Nitride Surface Modification Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.