Aluminum Silicon Carbide Shell

Aluminum Silicon Carbide Shell

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

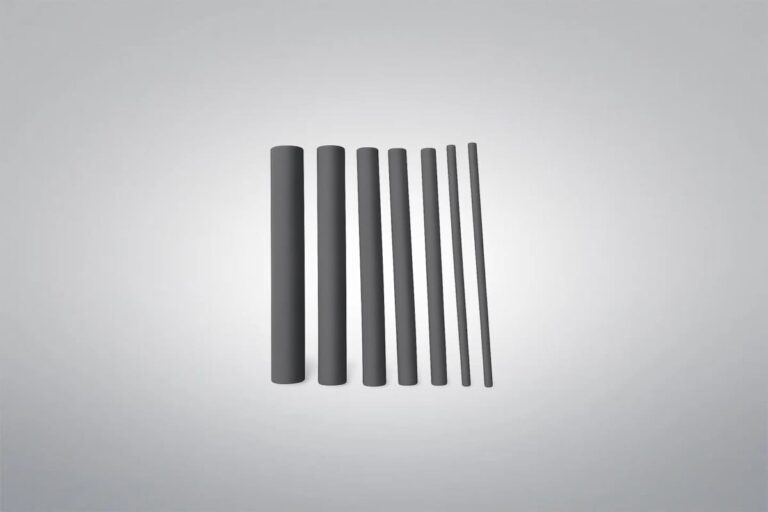

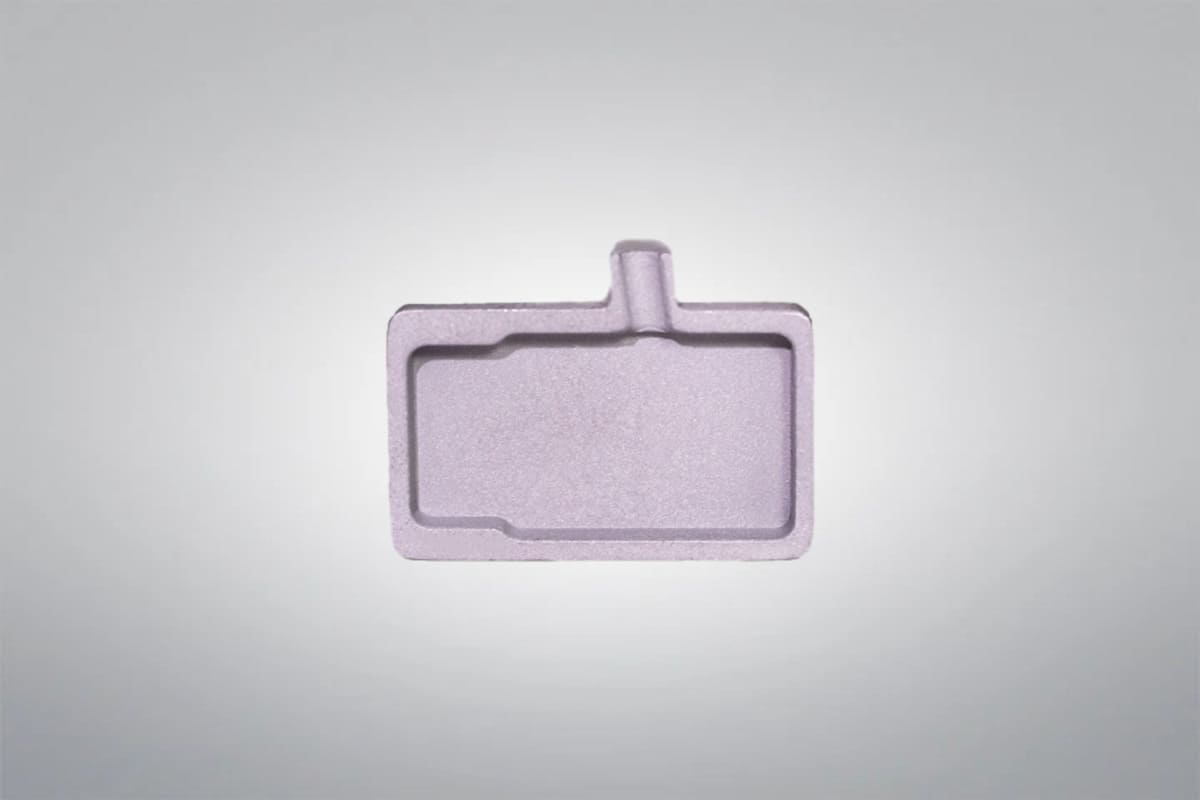

Aluminum Silicon Carbide Shell is designed for hermetic tube packaging, combining excellent thermal conductivity with a lightweight structure that helps reduce overall packaging weight and cost. It provides superior performance over traditional metal and ceramic materials in applications such as power electronics, electric power systems, power microwave devices, optoelectronic conversion, communication base station signal amplifiers, and hybrid circuits. As a leading supplier and manufacturer of premium silicon carbide products, Shanghai Yuepeng can supply high-quality Aluminum Silicon Carbide Shell with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Aluminum Silicon Carbide Shell Data Sheet

| Chemical Formula: | Al-SiC |

| Shape: | Shell |

| Dimension: | Standard or customized |

Aluminum Silicon Carbide Shell Description

Aluminum Silicon Carbide Shell serves as an advanced solution for hermetic tube packaging, offering a unique combination of high thermal conductivity, low density, and mechanical strength. By replacing heavier traditional metal and ceramic materials, it effectively reduces the overall weight of the package, enhances heat dissipation efficiency, and lowers production costs. Its stability and reliability under demanding operating conditions make it an excellent choice for applications in power electronics, high-frequency microwave systems, optoelectronic conversion devices, communication base station amplifiers, and hybrid circuit modules. This material’s balanced performance profile enables higher power densities, longer service life, and improved efficiency in critical electronic systems.

Aluminum Silicon Carbide Material Chemical Composition

| Technology | Material Reference Code | Volume Fraction | Performance Advantages | Application Directions | |

| SiC (%) | Al (%) | ||||

| RSPM + HIP (Rapid Solidification + HIP) | HMA15 | 15 | 85 | ☑High specific strength & stiffness ☑Low density ☑Excellent wear resistance ☑Good heat resistance | ☑Lightweight and wear-resistant components ☑Alternative to aluminum alloys, cast steel, cast iron, and titanium alloys ☑Brake components, pistons, connecting rods, fighter belly fins, helicopter rotor forgings |

| HMA30 | 30 | 70 | |||

| HMA40 | 40 | 60 | ☑High specific strength & stiffness ☑High micro-yield strength ☑Low thermal expansion ☑High thermal conductivity | ☑Aerospace and defense applications ☑Optical mirrors, inertial navigation system components ☑Alternative to beryllium, glass-ceramics, quartz glass | |

| HMA50 | 50 | 50 | |||

| Pressure Infiltration (PI) | HMA55 | 55 | 45 | ☑High specific modulus ☑Low density ☑Low thermal expansion ☑High thermal conductivity | ☑Thermal management materials for military and civilian use ☑Military IGBT substrates, PCB substrates, heat dissipation baseplates ☑Electronic component bases and housings, power amplifier module housings and bases ☑Alternative to W/Cu, Mo/Cu, Kovar alloys |

| HMA65 | 65 | 35 | |||

| HMA70 | 70 | 30 | |||

Aluminum Silicon Carbide Shell Features

- High Thermal Conductivity: Efficiently dissipates heat to maintain optimal operating temperatures in high-power applications.

- Lightweight Structure: Significantly reduces overall packaging weight compared to traditional metal or ceramic shells.

- Cost-Effective: Lowers manufacturing and material costs while maintaining high performance and reliability.

- Excellent Mechanical Strength: Provides robust structural support and durability under demanding operating conditions.

- Wide Application Compatibility: Suitable for power electronics, microwave systems, optoelectronic devices, and hybrid circuit modules.

Aluminum Silicon Carbide Shell Applications

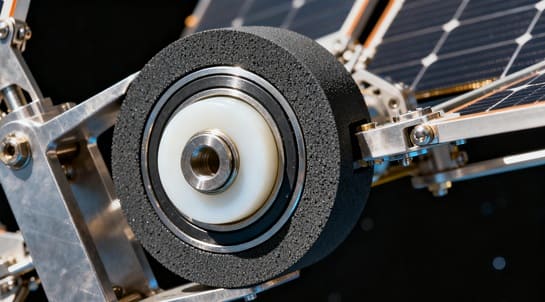

- Aerospace Structures: Used in satellite housings and aircraft shells where low weight and high stiffness are required to improve payload efficiency and structural reliability.

- Defense Protection: Applied in lightweight armor shells and protective casings, offering excellent ballistic resistance and durability without adding excessive weight.

- Electronics Enclosures: Serves as casings for high-power electronic devices, ensuring thermal stability, mechanical strength, and resistance to thermal stress.

- Automotive Components: Utilized in engine covers, housings, and structural shells to reduce overall vehicle weight while maintaining high wear resistance.

- Industrial Equipment: Integrated into high-performance machinery shells that need both corrosion resistance and long-term structural stability in harsh environments.

- Automotive Industry

- Semiconductor and Electronics

- Aerospace and Defense Applications

- Defense and Aerospace

- Industrial Coatings and Seals

Aluminum Silicon Carbide Material Properties

Aluminum Silicon Carbide Ceramic Packaging

Aluminum Silicon Carbide Ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.