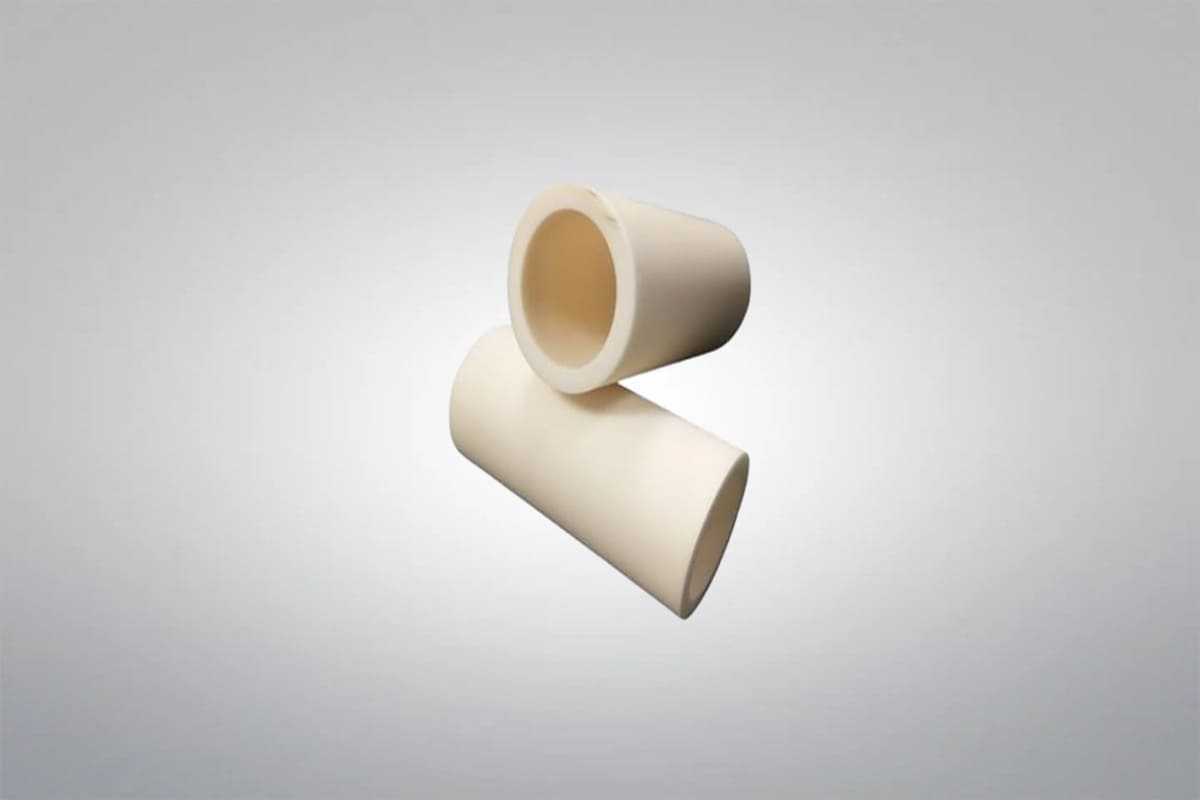

Beryllium Oxide Tube/Pipe

Beryllium Oxide Tube/Pipe

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

Beryllium Oxide Tube/Pipe offers exceptional thermal conductivity, high dielectric strength, and excellent resistance to thermal shock, making it an ideal choice for high-power electronic and microwave applications. With a combination of electrical insulation and heat dissipation capabilities, it’s widely used in vacuum electronics, RF devices, and aerospace components. Its high melting point and mechanical stability also make it suitable for use in extreme environments. As a leading supplier and manufacturer of premium beryllium oxide products, Shanghai Yuepeng can supply high-quality Beryllium Oxide Tube/Pipe with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Beryllium Oxide Tube/Pipe Data Sheet

| Color: | White |

| Chemical Formula: | BeO |

| Dimension: | customized |

| Machining Accuracy: | 0.01 mm |

| Surface Roughness: | 0.1 μm |

Beryllium Oxide Tube/Pipe Description

Beryllium Oxide Tube/Pipe delivers exceptional thermal conductivity combined with strong electrical insulation, making it a top choice for high-power electronic and microwave systems. It performs reliably under extreme temperatures and maintains structural integrity in vacuum, high-voltage, or chemically reactive environments. With low dielectric constant and high strength, it supports applications in aerospace, RF electronics, and advanced semiconductor systems. Its precision form and thermal shock resistance also make it suitable for demanding heat transfer setups.

Beryllium Oxide Tube/Pipe Chemical Compositions

| Element | Content (ppm) |

|---|---|

| Boron (B) | 2 |

| Aluminum (Al) | 46 |

| Chromium (Cr) | 8 |

| Iron (Fe) | 32 |

| Magnesium (Mg) | 1000 |

| Manganese (Mn) | 2 |

| Nickel (Ni) | 9 |

| Titanium (Ti) | 5 |

| Sodium (Na) | 173 |

| Calcium (Ca) | 31 |

| Silicon (Si) | 2100 |

Beryllium Oxide Tube/Pipe Features

- High Thermal Conductivity: Offers superior heat dissipation, comparable to metals like aluminum, making it ideal for high-power thermal management.

- Excellent Electrical Insulation: Provides strong dielectric properties, ensuring safety and performance in high-voltage systems.

- Mechanical Strength and Rigidity: Maintains structural integrity under stress, even at elevated temperatures.

- Thermal Shock Resistance: Withstands rapid temperature changes without cracking, perfect for dynamic thermal environments.

- Chemical Stability: Resists corrosion and degradation in harsh chemical and vacuum environments.

Beryllium Oxide Tube/Pipe Applications

- High-Power Electronics: Beryllium oxide tubes are used as insulators and heat conduits in microwave transmitters, radar systems, and RF devices where efficient heat transfer and electrical insulation are both essential.

- Semiconductor Manufacturing: They serve as protective housings and insulators in semiconductor fabrication equipment, ensuring thermal stability and preventing contamination in high-temperature processes.

- Vacuum and Nuclear Systems: These tubes are employed in vacuum devices and nuclear reactors due to their low outgassing, excellent radiation resistance, and ability to maintain structural integrity under extreme conditions.

- Laser and Optical Devices: Beryllium oxide pipes are used in laser assemblies and optical systems to dissipate heat effectively, helping maintain precision and consistent performance.

- Medical and Aerospace Equipment: In advanced medical imaging devices and aerospace systems, BeO tubes function as thermal conductors and insulating components, combining lightweight structure with outstanding thermal management.

- High-Temperature Furnaces

- Medical Devices

- Aerospace and Automotive

- Optical Devices

- Semiconductor Manufacturing

Beryllium Oxide Ceramic Properties

Beryllium Oxide Ceramic Material Machining

Beryllium Oxide (BeO) Ceramic is valued for its exceptional thermal conductivity, electrical insulation, and high melting point. These qualities make it widely used in electronics and high-temperature applications, but its hardness and brittleness require special machining approaches. Key machining considerations include:

- Cutting: Precision diamond-coated tools or laser cutting are essential to avoid microcracks and maintain clean edges, as BeO’s brittleness can lead to chipping during conventional cutting.

- Grinding: Fine diamond grinding wheels enable accurate shaping and surface finishing while minimizing the risk of fractures, especially important for small or complex parts.

- Drilling: Ultrasonic machining or abrasive waterjet methods are preferred to produce precise holes without causing thermal damage or cracks.

- Surface Finishing: Polishing techniques enhance surface smoothness and electrical insulation properties, crucial for applications demanding high dielectric performance and reliability.

Beryllium Oxide Ceramic Packaging

Beryllium Oxide Ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of the products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.