Boron Carbide Powder

Boron Carbide Powder

Purity: 99%

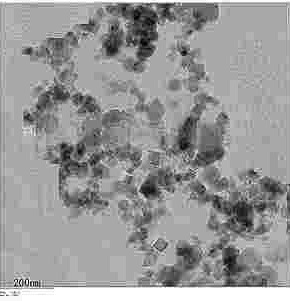

Particle Size: 0.1 μm, 0.8 μm, 2.3 μm, or customized

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

Boron Carbide Powder is a superhard ceramic material composed of boron and carbon, commonly represented by the chemical formula B₄C. With a Vickers hardness exceeding 30 GPa, it ranks among the hardest known materials, just after diamond and cubic boron nitride. Its exceptional hardness, low density, and strong chemical stability make it a key material in a wide range of industrial applications. As a leading supplier and manufacturer of premium boron carbide products, Shanghai Yuepeng can supply high-quality boron carbide powder with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Boron Carbide Powder Data Sheet

| Reference Code: | HMCP-1705 |

| Purity: | 99% |

| CAS: | 12069-32-8 |

| Color: | Dark grey |

| Chemical Formula: | B₄C |

| Particle Size: | 0.1 μm, 0.8 μm, 2.3 μm, or customized |

| Density: | 2.508~2.512 g/cm3 |

| Melting Point: | 2,350°C |

| Boiling point: | 3500°C |

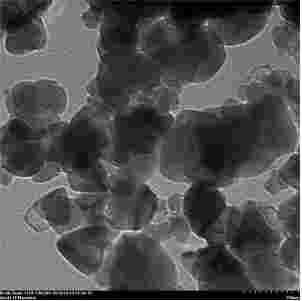

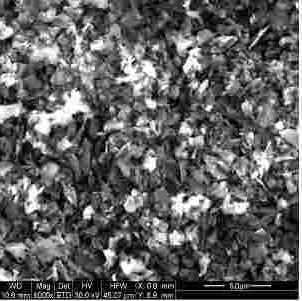

| shape: | Irregular |

Boron Carbide Powder Description

Boron Carbide Powder is known for its ultra-high hardness, low density, and exceptional resistance to wear and chemical corrosion, making it a preferred material in ballistic armor, abrasives, and high-temperature applications. Its fine particle size and stable chemical properties ensure consistent performance in ceramic processing, metal matrix composites, and nuclear-grade applications. In addition to this irregular powder form, Shanghai Yuepeng also provides spherical Boron Carbide Powder, which offers improved flowability and packing density for use in additive manufacturing, thermal spraying, and advanced powder metallurgy.

Boron Carbide Powder Specifications

| Product | Chemical Composition (%) | |||||

| B4C | B | C | N | O | ||

| 79.0 | 19.2 | 0.2 | 1.4 | |||

| Particle Size Distribution | ||||||

| D10 | D50 | D90 | ||||

| 0.1μm | 0.8μm | 2.3μm | ||||

| BET | ||||||

| 15 m2/g | ||||||

Boron Carbide Powder Advantages

- Ultra-high hardness

- Low density

- Excellent chemical stability

- High thermal resistance

- Fine particle control

- Versatile application range

Boron Carbide Powder Applications

- Abrasives: Used in grinding, lapping, and polishing hard materials such as ceramics, tungsten carbide, and gemstones due to their extreme hardness.

- Armor Materials: Applied in the production of lightweight bulletproof vests, vehicle armor, and protective shields, providing high ballistic resistance.

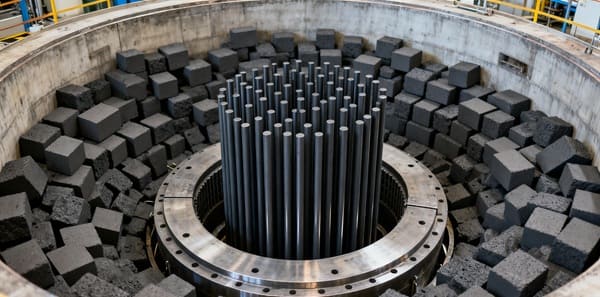

- Nuclear Industry: Utilized as a neutron absorber in control rods, shielding, and other nuclear applications because of its excellent neutron capture capability.

- Refractory Materials: Incorporated into high-temperature furnace linings and components, offering chemical resistance and thermal stability.

- Advanced Ceramics & Composites: Added to ceramic and composite materials to improve wear resistance, hardness, and mechanical strength for industrial and aerospace applications.

- Abrasives

- Advanced Ceramics & Composites

- Armor Materials

- Nuclear Industry

- Refractory Materials

Boron Carbide Powder Packaging

The Boron Carbide Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.