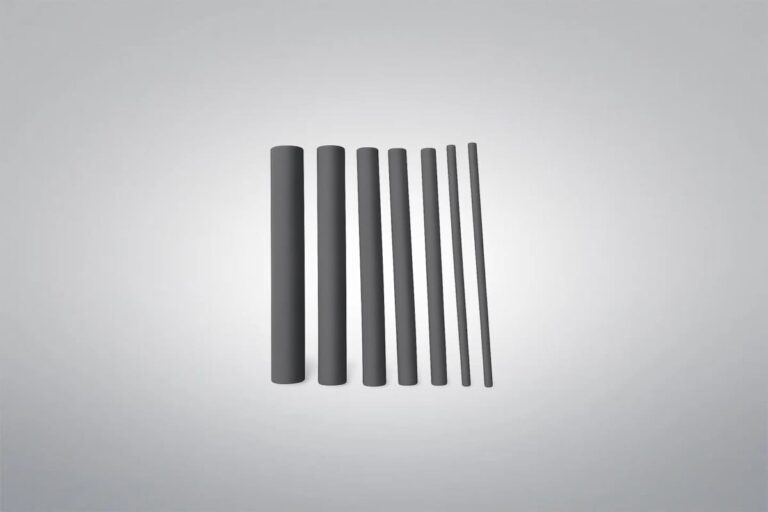

Magnesium Oxide Tube

Magnesium Oxide Tube

Purity: ≥99%

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

Magnesium oxide tube is a high-purity ceramic known for its excellent thermal stability, electrical insulation, and corrosion resistance. With a melting point of 2800°C, it performs well in high-temperature environments, making it ideal for thermocouple protection, furnace insulation, and metal processing. Its low dielectric loss and high electrical resistivity also make it suitable for electrical applications. As a leading supplier and manufacturer of premium graphite products, Shanghai Yuepeng can supply high-quality magnesium oxide tube with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Magnesium Oxide Tube Sheet

| Color: | White/Ivory |

| Chemical Formula: | MgO |

| Refractoriness: | Super high grade (Refractoriness > 2000°) |

| Density: | 3.30~3.55 g/cm3 |

| Melting Point: | 2800°C±13°C |

| Dimension: | customized |

| Working temperature: | 2400°C |

| Compressive strength: | 1000 MPa |

| Flexural strength: | 300 MPa |

| Surface: | Glass/Polished |

| Processing services: | Bending, welding, punching, decoiling, cutting, molding |

Magnesium Oxide Tube Description

Magnesium oxide tube is a refractory ceramic product known for its ability to withstand extreme heat and harsh chemical environments. With a high melting point and low electrical conductivity at room temperature, it’s an effective solution for insulating elements in high-temperature systems. These tubes are often used in scientific equipment, thermal processing lines, and nuclear-related applications where stability and purity are critical.

Magnesium Oxide Tube Features

- High temperature resistance up to 2400°C in oxidizing or inert atmospheres

- Excellent thermal insulation and low thermal conductivity

- High electrical resistivity at room temperature

- Chemically stable against most acids and basic slags

- Good compatibility with thermocouples and heating elements

Magnesium Oxide Tube Applications

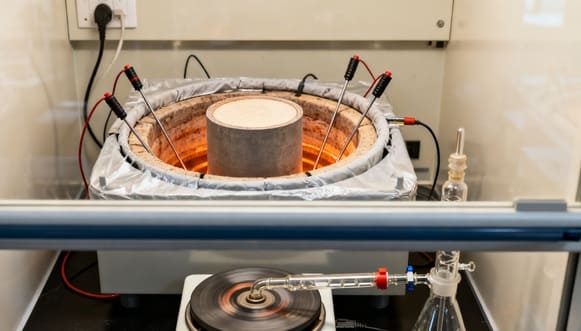

- High-Temperature Furnaces: Magnesium oxide tubes are widely used as protective and insulating components in high-temperature furnaces, ensuring stability and preventing heat loss during operation.

- Thermocouple Protection: These tubes serve as protective sheaths for thermocouples, safeguarding temperature sensors from oxidation, corrosion, and mechanical damage in extreme environments.

- Electrical Insulation: MgO tubes are used in electric heating elements and other electronic systems to provide effective insulation and prevent electrical short circuits.

- Chemical Processing Equipment: Due to their excellent resistance to corrosion and chemical attack, magnesium oxide tubes are applied in reactors and systems handling aggressive substances.

- Laboratory Applications: They are used in laboratory settings for sample heating, gas flow control, and high-temperature experiments, offering reliable performance and long service life.

- High-Temperature Laboratories

- High-Temperature Furnaces

- Thermal Management Materials

- Chemical Industry

- Laboratory Equipment

Magnesium Oxide Material Properties

Magnesium Oxide Ceramic Machining

Magnesium oxide can be machined in green or bisque form before sintering, and to a limited extent in its fully sintered state. In its pre-sintered state, the material is relatively soft and easier to shape, but like many ceramics, it undergoes significant shrinkage—up to 20%—during sintering, which can affect final dimensions. Fully sintered magnesium oxide is very hard and brittle, requiring diamond tools and precision equipment for any post-sintering machining.

Machining Methods and Considerations

- Green or Bisque Machining: Easier to cut and form, suitable for complex shapes before firing.

- Sintering Shrinkage: Expect about 15–20% dimensional reduction during sintering, which impacts tolerance control.

- Post-Sintering Machining: Requires diamond grinding tools due to the material’s hardness and brittleness.

- Fragility: Fully sintered MgO is prone to chipping and fracture if not handled with care during machining.

- Tooling and Time: Machining dense MgO ceramics is time-consuming and requires specialized equipment.

Magnesium Oxide Ceramic Packaging

Magnesium Oxide Ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of the products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.