Mn2AlB2 MAB Phase Powder

Mn2AlB2 MAB Phase Powder

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

Mn2AlB2 MAB Phase Powder is a gray-black layered boride combining metal-like conductivity with ceramic-like stability. Known for its durability, oxidation resistance, and versatile functionality, it is widely studied for coatings, electronics, and advanced structural applications. As a leading supplier and manufacturer of premium MAB Phase Powder products, Shanghai Yuepeng can supply high-quality Mn2AlB2 MAB Phase Powder with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Mn2AlB2 MAB Phase Powder Data Sheet

| Purity: | ≥99% |

| Size : | 200 mesh (~78 µm), 300 mesh (56 ~µm), 400 mesh (~38 µm), 500 mesh (~20 µm), or customized |

Mn2AlB2 MAB Phase Powder Description

Mn2AlB2 MAB Phase Powder is a layered ternary boride material belonging to the unique family of MAB phases, which combine both metallic and ceramic characteristics. This compound, formed by manganese (Mn), aluminum (Al), and boron (B), crystallizes in an orthorhombic structure that provides a balance of electrical conductivity, thermal stability, and mechanical strength. Its distinctive structure enables exceptional oxidation resistance and moderate hardness, while maintaining good machinability compared to traditional ceramics. These properties make Mn2AlB2 highly attractive for applications in functional coatings, electronic devices, energy storage, and as a candidate material for high-temperature structural components. With its layered nature, the material also opens pathways for potential exfoliation into 2D derivatives, similar to MXenes, but with unique chemistry and functional possibilities.

Mn2AlB2 MAB Phase Powder Specifications

| Product Name | Manganese Aluminum Boride |

|---|---|

| Chemical Formula | Mn2AlB2 |

| Particle Size (Mesh/µm) | 200 mesh (~78 µm), 300 mesh (56 ~µm), 400 mesh (~38 µm), 500 mesh (~20 µm), or customized |

| Purity | ≥99% |

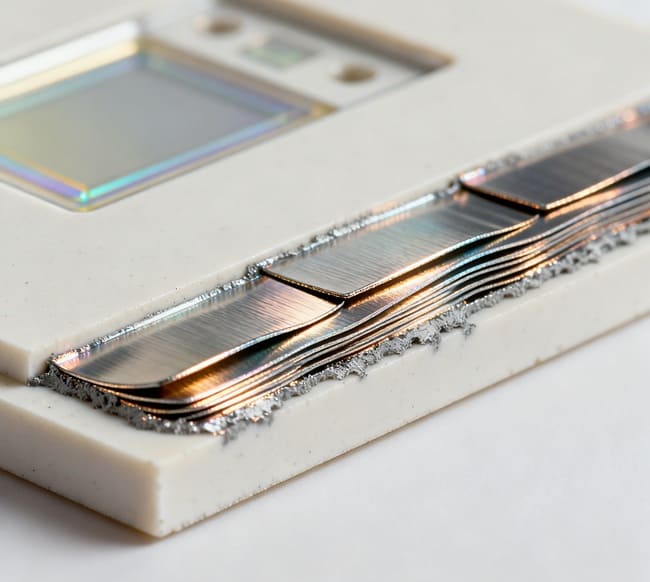

| Structure | Layered bulk |

| Color | Gray-black |

| Forming Method | Pressureless sintering |

| Shelf Life | 1 year (store in dry, dark conditions) |

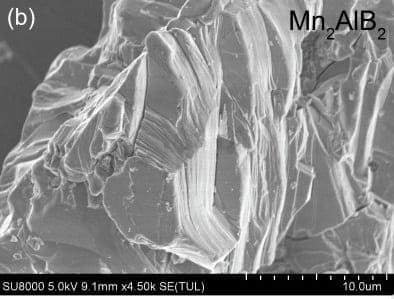

Mn2AlB2 MAB MXene Phase Powder SEM

Mn2AlB2 MAB Phase Powder Features

- Layered Crystal Structure: Belonging to the MAB (Mn-Al-B) phase family, this structure features a unique layered configuration that combines metallic and ceramic characteristics for multifunctional applications.

- High Purity (≥99%): Ensures reliable material performance in research and industrial uses, minimizing impurities that could affect structural or thermal stability.

- Excellent Thermal and Chemical Stability: Exhibits resistance to oxidation and chemical corrosion, suitable for high-temperature and harsh environment applications.

- Customizable Particle Size: Available in multiple mesh sizes (200–500 mesh), providing flexibility for various processing methods, including sintering, coating, and composite preparation.

- Potential for Advanced Applications: Promising candidate in electromagnetic shielding, energy storage systems, and next-generation structural-functional materials research.

Mn2AlB2 MAB Phase Powder Applications

- Magnetic and Electronic Devices: Mn2AlB2 exhibits interesting magnetic properties, making it suitable for use in magnetic sensors, data storage systems, and spintronic materials.

- High-Temperature Structural Materials: With its layered crystal structure and good thermal stability, Mn2AlB2 is applied in components that operate under elevated temperatures, such as heat-resistant parts and protective barriers.

- Protective and Functional Coatings: Mn2AlB2 can be used to create coatings that enhance oxidation resistance, corrosion resistance, and wear performance on metal or ceramic substrates.

- Composite Reinforcement: When used as a reinforcing phase in composites, Mn2AlB2 improves mechanical strength, hardness, and thermal conductivity, enhancing overall material durability.

- Material Science and Research: Mn2AlB2 serves as a model system in studying magnetic MAB phases and the relationship between structure, bonding, and physical properties for advanced material development.

- Electrical and Thermal Conductive Parts

- High-Temperature Structural Materials

- Protective Coatings

- Refractory and Composite Materials

- Research and Development of Novel Materials

Download

Get A Quote

We will check and get back to you in 24 hours.