Molybdenum Copper Alloy

Molybdenum Copper Alloy

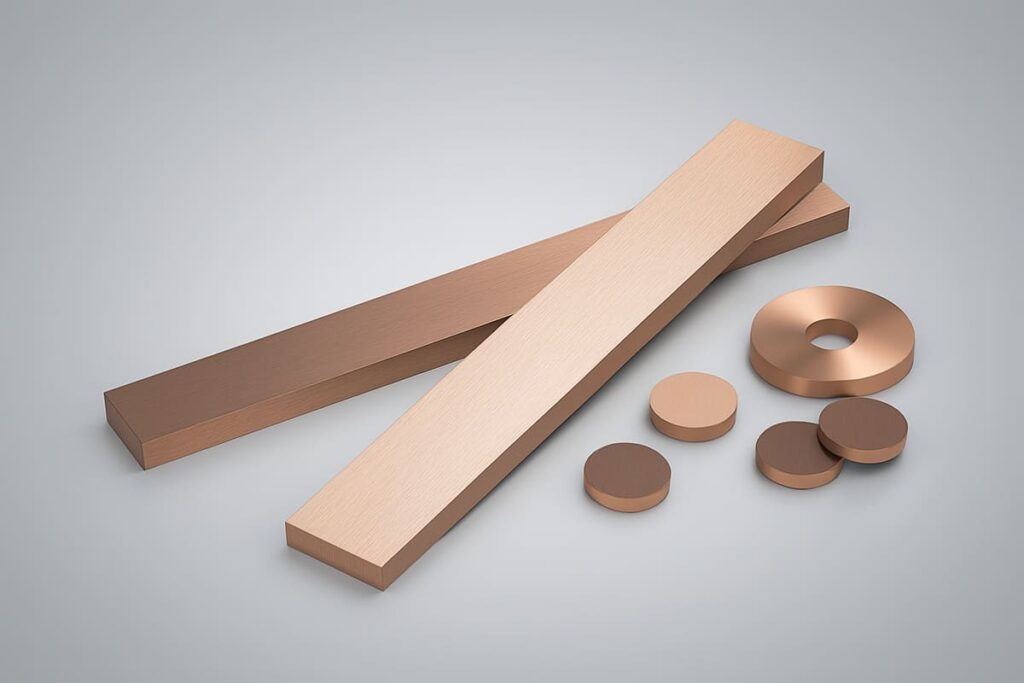

Molybdenum Copper Alloy is a high-performance material combining the benefits of molybdenum and copper. It offers an unique combination of thermal and electrical conductivity. The molybdenum-to-copper ratio can be customizable for various applications. As a leading supplier and manufacturer of premium molybdenum products, Shanghai Yuepeng utilizes advanced machining centers to produce high-precision molybdenum copper alloy products for a wide range of applications.

Molybdenum Copper Alloy Data Sheet

| Reference: | HMMO1098 |

| Material: | Mo90Cu10, Mo85Cu15, Mo80Cu20, Mo70Cu30, Mo60Cu40, Mo50Cu50, Mo40Cu60, or customized |

| Purity: | 99.9%-99.99% |

| Standard: | ASTM B387 & ASTM B386 |

| Temper: | Annealed and Unannealed |

Molybdenum Copper Alloy

Molybdenum Copper Alloy are composite rolled by fusion infiltration of molybdenum-copper alloys and molybdenum-copper sandwich structure bimetallic and mechanically processed into the final product, featuring an adjustable thermal expansion coefficient and thermal conductivity. It offers lower density but a higher thermal expansion coefficient than tungsten-copper (WCu) alloy. Molybdenum Copper Alloys offer good strength and plasticity at room and intermediate temperatures. At high temperatures, copper melts and evaporates, absorbing heat. This property makes the alloy ideal for high-temperature applications like rocket nozzle liners and electrical contacts in arc conditions. Shanghai Yuepeng provides high-precision Mo-Cu alloy products with various specifications, all crafted to ensure exceptional quality and customer satisfaction.

Molybdenum Copper Alloy Specifications

| Material | Mo Content | Cu Content | Density | Thermal Conductivity, 25℃ | CTE, 25℃ |

| Wt% | Wt% | g/cm3 | W/M∙K | (10-6/K) | |

| Mo90Cu10 | 90±1 | Balance | 10 | 150-160 | 5.6 |

| Mo85Cu15 | 85±1 | Balance | 10 | 160-180 | 6.8 |

| Mo80Cu20 | 80±1 | Balance | 9.9 | 170-190 | 7.7 |

| Mo70Cu30 | 70±1 | Balance | 9.8 | 180-200 | 9.1 |

| Mo60Cu40 | 60±1 | Balance | 9.66 | 210-250 | 10.3 |

| Mo50Cu50 | 50±0.2 | Balance | 9.54 | 230-270 | 11.5 |

| Mo40Cu60 | 40±0.2 | Balance | 9.42 | 280-290 | 11.8 |

Molybdenum Copper Alloy Features

- High conductivity

- Adjustable low coefficient of thermal expansion

- Non-magnetic

- Low gas content

- Good vacuum properties

- Good machinability and special high-temperature properties

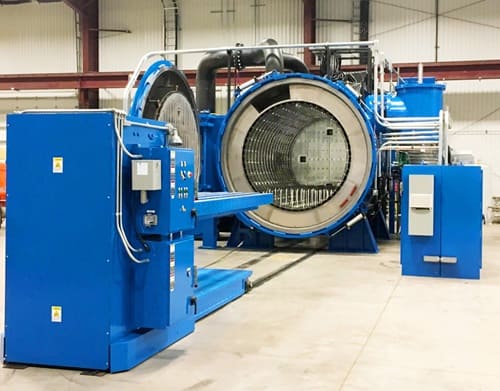

Molybdenum Copper Alloy Machining Service

Shanghai Yuepeng has advanced machining centers equipped with various high-precision processing equipment, enabling us to offer multiple machining services such as turning, milling, grinding, and drilling. Whether for large-scale production or customized small-batch orders, we guarantee high precision and performance to meet customer’s specific requirements. The following are methods we will use during processing:

- Isostatic Pressing

- Forging

- Extrusion

- Molding

- Injection Molding

- Rolling

- Electrical Discharge Machining (EDM)

- Milling

- Turning

Molybdenum Copper Alloy Applications

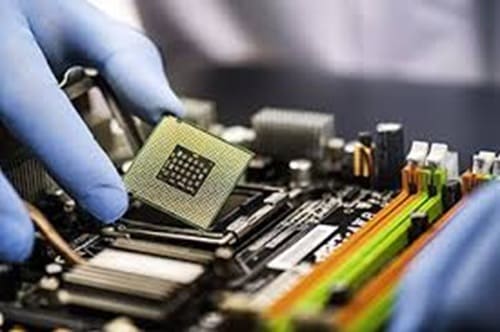

- Electronics Industry: Molybdenum-copper alloys are commonly used to manufacture high-power microelectronic devices and electronic packaging materials.

- Aerospace: Molybdenum-copper alloys are also used to manufacture aircraft engine combustion chamber wall plates and turbine blades due to their high temperature and oxidation resistance.

- Photovoltaics and Petrochemicals: Molybdenum-copper alloys are used to prepare equipment for use in high-temperature and high-pressure environments.

- Machining: Molybdenum-copper alloys are used to manufacture high-strength and wear-resistant mechanical components.

Molybdenum Copper Alloy Packaging

The Molybdenum Copper Alloy products are carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Molybdenum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.