Molybdenum Ingot

Molybdenum Ingot

Molybdenum Ingot is made of high-purity molybdenum material, exhibiting high melting point, excellent thermal conductivity, and low thermal expansion. As a leading supplier and manufacturer of premium molybdenum products, Shanghai Yuepeng utilizes advanced machining centers to produce high-precision molybdenum and molybdenum alloy ingots for a wide range of applications.

Molybdenum Ingot Data Sheet

| Reference: | HMMO1350 |

| Dimensions: | 2-3 cm × 3-8 cm × 6-12 cm, or customized according to specific requirements |

| Shape: | Customized |

| Material: | Pure Mo361 |

| Purity: | 99.95%-99.99% |

| Surface: | Pickled, Turned, or Ground |

| Temper: | Annealed or Unannealed |

Molybdenum Ingot

Molybdenum Ingot is generally the least costly metallic form and is useful in general applications. Shanghai Yuepeng can manufacture molybdenum ingots with the highest possible density using crystallization, solid state, and other ultra-high purification processes such as sublimation. The regular size is 2-3 cm × 3-8 cm × 6-12 cm. Other sizes and shapes can be customized according to specific requirements.

Molybdenum Ingot Chemical Composition

| Material | Mo | Impurities, (≤%) | |||||||||

| Al | Ca | Fe | Mg | Ni | Si | C | N | O | La2O3 | ||

| Mo1 | Bal. | 0.002 | 0.002 | 0.010 | 0.002 | 0.005 | 0.01 | 0.01 | 0.003 | 0.008 | – |

| Mo2 | Bal. | 0.005 | 0.004 | 0.015 | 0.005 | 0.005 | 0.01 | 0.02 | 0.003 | 0.020 | – |

Molybdenum Ingot Features

- High melting point

- High strength

- Excellent thermal conductivity

- Low thermal expansion coefficient

- Good corrosion resistance

- Good mechanical properties

Molybdenum Ingot Applications

- Steel Industry: Molybdenum ingots are used to produce alloy steels, stainless steels, and tool steels to improve strength, toughness, and corrosion resistance.

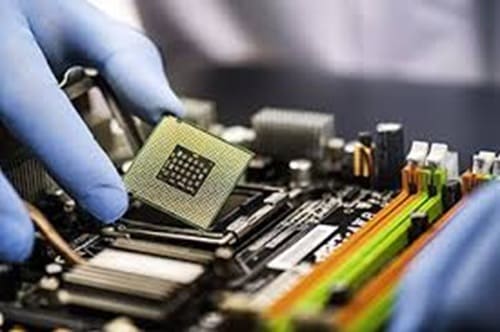

- Electronics Industry: Molybdenum ingots are used as support material for electronic devices such as semiconductor substrates and electrodes.

- Chemical Industry: Molybdenum ingots are used to manufacture high-temperature and corrosion-resistant chemical equipment such as reactors and heat exchangers.

- Aerospace: Molybdenum ingots are used to manufacture high-temperature components for aerospace vehicles and have good creep resistance and ductility.

- Medical Equipment: Molybdenum ingots are also used in making high-temperature components in medical equipment and radioisotope containers.

Molybdenum Ingot Packaging

The Molybdenum Ingot is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Molybdenum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.