Molybdenum Powder

Molybdenum Powder

Molybdenum Powder is made of high-purity molybdenum material, exhibiting high surface area and wide ranges of particle size distribution. It is highly versatile in the fields of metallurgy and materials science. As a leading supplier and manufacturer of premium molybdenum products, Shanghai Yuepeng utilizes advanced machining centers to produce high-precision molybdenum and molybdenum alloy powders for a wide range of applications.

Molybdenum Powder Data Sheet

| Reference: | HMMO1086 |

| Material: | Pure Mo361 |

| Purity: | 99.95%-99.99% |

| Shape: | Irregular or Spherical |

| Particle Size: | FSSS 1-10 μm, 0-25 μm, 15-53 μm, 53-105 μm, 53-150 μm, or sieve as required |

Molybdenum Powder

Molybdenum is a silver-grey metal with a melting point of 2623 ℃ and a density of 10.2 g/cm3. It is one of the commercially available metals with the lowest coefficient of thermal expansion. Molybdenum Powder is commonly produced by reducing ammonium paramolybdate or calcined MoO3 with hydrogen. The oxygen content can be reduced to lower levels through specific reduction conditions. Shanghai Yuepeng can supply high-quality irregular and spherical molybdenum powder with particle sizes from coarse to ultra-fine.

Molybdenum Powder Specifications

| Product | HM-Mo-1 | HM-Mo-2 | HM-Mo-3 | |

| Mo content (%) | ≥99.95 | ≥99.90 | ≥99.80 | |

| Impurities content (≤%) | Cd | 0.001 | — | 0.001 |

| Fe | 0.005 | 0.006 | 0.030 | |

| Al | 0.0015 | 0.002 | 0.005 | |

| Bi | 0.0010 | — | 0.001 | |

| C | 0.0060 | 0.010 | 0.020 | |

| Ca | 0.0020 | 0.002 | 0.004 | |

| Sb | 0.0010 | — | 0.001 | |

| Cr | 0.0030 | — | — | |

| Cu | 0.0010 | 0.001 | — | |

| Mg | 0.0020 | 0.003 | 0.005 | |

| Mn | 0.0005 | — | — | |

| Ni | 0.0010 | 0.003 | 0.005 | |

| O | 0.1500 | 0.25 | 0.25 | |

| P | 0.0010 | 0.001 | 0.005 | |

| Pb | 0.0010 | — | 0.001 | |

| Sn | 0.0010 | — | 0.001 | |

| Si | 0.0020 | 0.003 | 0.010 | |

| Ti | 0.0010 | — | — | |

| W | 0.0150 | — | — | |

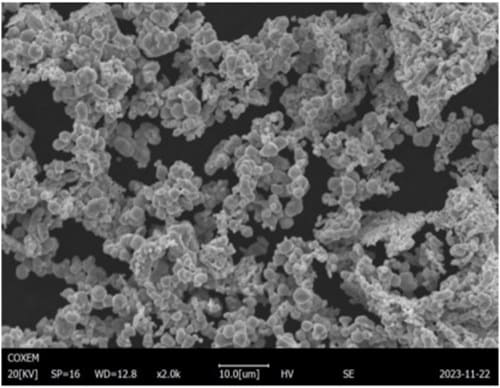

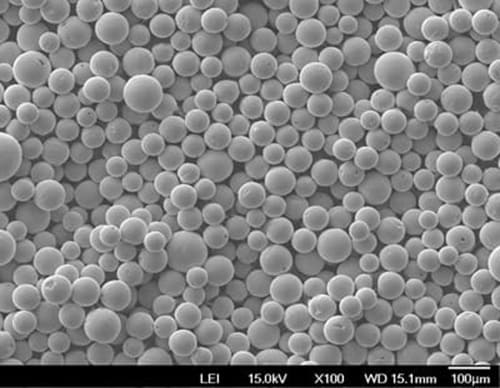

Molybdenum Powder SEM

Irregular Molybdenum Powder SEM Molybdenum Spherical Powder SEM

Molybdenum Powder Features

- High-temperature strength and creep resistance

- Excellent corrosion resistance

- Good thermal and electrical conductivity

- Low coefficient of thermal expansion

- High hardness and wear resistance

- Good lubricity in the vulcanizing atmosphere

- Available in various particle size distributions

Molybdenum Powder Production Method

Molybdenum Powder can be produced using various methods, with hydrogen reduction being the most commonly employed industrial process. This method allows precise control over the powder’s morphology, particle size, and purity.

- Hydrogen Reduction: Reduction of molybdenum trioxide with hydrogen to produce molybdenum powder.

- Thermal Decomposition: Heating molybdenum compounds such as ammonium molybdate to form molybdenum oxide followed by hydrogen reduction.

- Electrolytic Production: Molybdenum powder precipitates are produced by aqueous electrolytic precipitation from an acidic molybdate solution.

- Calcium Thermal Reduction: Reduction of molybdenum trioxide using calcium.

Molybdenum Powder Applications

- Powder Metallurgy: Molybdenum powder is an important raw material for producing molybdenum alloys and molybdenum products, and is widely used to manufacture high-strength, high-temperature alloys and corrosion-resistant alloys.

- Electronic Industry: Molybdenum powder is also used to manufacture electronic components such as electrodes, semiconductor devices, and electrode wires for EDM machines.

- Chemical Industry: Molybdenum powder is used as a catalyst and corrosion-resistant material in the chemical and petroleum industries.

- Aerospace: Molybdenum powder is used to manufacture high-temperature components such as gas turbine blades and guide vanes for jet engines.

- Glass and Ceramics Industry: Molybdenum powder is also used to manufacture heaters for high-temperature furnaces and electrodes for glass-melting furnaces.

Molybdenum Powder Packaging

The high-quality molybdenum powder will be carefully handled to prevent damage during storage and transportation. Shanghai Yuepeng offers vacuum-sealed packaging, including 100g/bag, 500g/bag, 1kg/bag, and 25kg/drum, or can offer customized packaging as per specific requirements.

Molybdenum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.