Molybdenum Tube/Pipe

Molybdenum Tube/Pipe

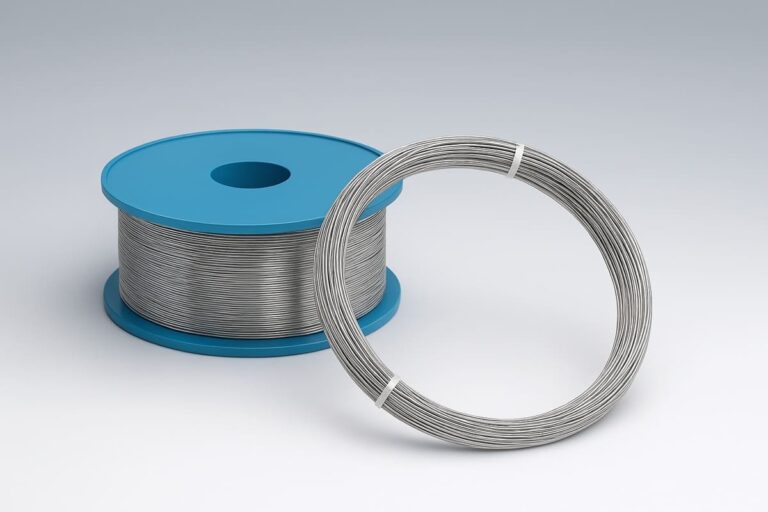

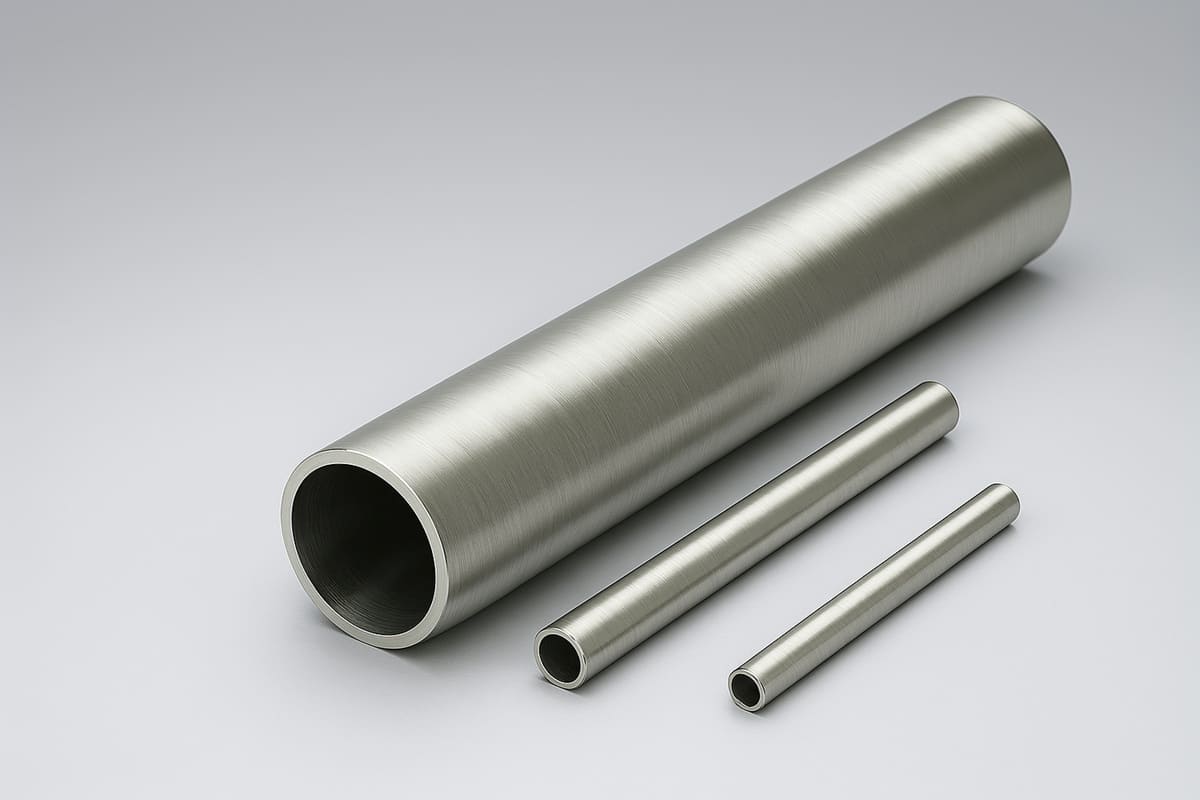

Molybdenum Tube/Pipe is made of high-purity molybdenum material through powder metallurgy, molding, sintering, and forging, exhibiting high melting point, excellent thermal conductivity, and low thermal expansion. As a leading supplier and manufacturer of premium molybdenum products, Shanghai Yuepeng utilizes advanced machining centers to produce high-precision molybdenum and molybdenum alloy tubes and pipes for a wide range of applications.

Molybdenum Tube/Pipe Data Sheet

| Reference: | HMMO1083 |

| Dimensions: | Outer Diameter: 3-500 mm Wall Thickness: 0.2-30 mm Length: 200-6000 mm |

| Shapes: | Cylinder, Square, or Rectangle (according to the cross-section) |

| Standard: | ASTM B387 |

| Material: | Pure Mo361, MoTZM (Mo364), Mo-Lanthanoxid (ML) |

| Purity: | 99.95%-99.99% |

| Density: | 9.8-10.2 g/cm3 |

| Temper: | Annealed or Unannealed |

Molybdenum Tube/Pipe

Molybdenum Tubes and Pipes are available in seamless and welded forms, excelling in operating environments up to 2000 ℃. They possess excellent thermal conductivity, low thermal expansion, and corrosion resistance. They are commonly applied to produce high-temperature furnace heating components. Shanghai Yuepeng can supply high-precision molybdenum and molybdenum alloy tubes and pipes with tight tolerances and various specifications. The customized solutions are available according to specific requirements.

Molybdenum Tube Specifications

| Outer Diameter (mm) | Wall Thickness (mm) | Length (mm) | |||

| Size | Tolerance | Size | Tolerance | Size | Tolerance |

| <100 | ±1.0 | <1 | ±0.1 | <100~150 | ±2.0 |

| 100~200 | ±2.0 | 1~3 | ±0.25 | 150~350 | ±3.0 |

| 200~300 | ±3.0 | 3~10 | ±0.5 | 350~650 | ±4.0 |

| 300~400 | ±5.0 | 10~20 | ±1.0 | 650 ~ 2000 | ±5.0 |

| >400 | ±7.0 | 20 ~ 30 max | ±1.0 | 2000 ~ 6000 max | ±5.0 |

Molybdenum Tube Available Stock Dimensions

| .125″ OD x .015″ wall x R/L | .500″ OD x .030″ wall x R/L |

| .187″ OD x .020″ wall x R/L | .625″ OD x .050″ wall x R/L |

| ..187″ OD x .020″ wall x R/L | .750″ OD x .060″ wall x R/L |

| .312″ OD x .020″ wall x R/L | .875″ OD x .040″ wall x R/L |

| .375″ OD x .025″ wall x R/L | 1.0″ OD x .050″ wall x R/L |

Molybdenum Tube/Pipe Production Process

- Raw Material: Select high-purity molybdenum powder.

- Powder Metallurgy: Mix with binder and compact into a green billet.

- Sintering: High-temperature sintering to remove the binder and increase density.

- Heat Treatment: Anneal to relieve stress and enhance properties.

- Surface Treatment: Clean and polish the surface.

- Cutting & Customization: Cut or customize according to requirements.

Molybdenum Tube/Pipe Surface Finish

Depending on the intended applications, molybdenum tubes and pipes have three main surface finishes as follows:

- Black: The surface is “as swaged” or “as drawn”, retaining a coating of processing lubricants and oxides.

- Cleaned: The surface is chemically cleaned to remove all lubricants and oxides.

- Ground: The surface is centerless ground to remove all coating and to achieve precise dimensions control.

Molybdenum Tube/Pipe Applications

- Aerospace and Defense: Because of its ability to withstand extreme environments and high temperatures, the molybdenum tube is commonly used to manufacture aircraft and spacecraft components.

- Medical Equipment: Molybdenum tubes are also used in X-ray tubes and other medical imaging equipment.

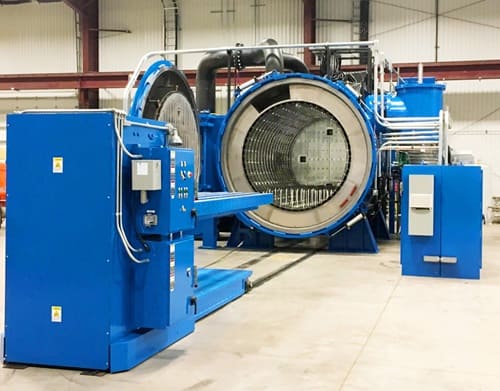

- High-Temperature Furnaces and Heating Elements: Molybdenum tubes are used as heating elements in high-temperature furnaces and heat-treatment equipment.

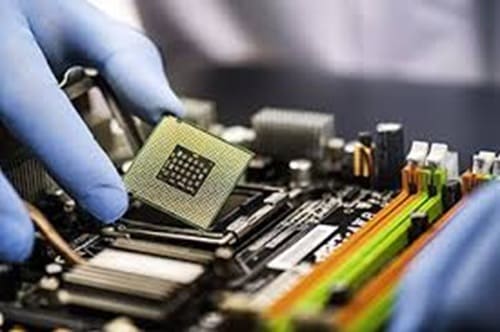

- Electronics and Semiconductor Industry: Molybdenum tubes are used in the semiconductor industry, especially in chemical vapor deposition (CVD) and physical vapor deposition (PVD) processes.

- Glass and Ceramic Production: Molybdenum tubes are used as electrodes in glass melting furnaces.

Molybdenum Tube/Pipe Packaging

The Molybdenum Tube/Pipe is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Molybdenum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.