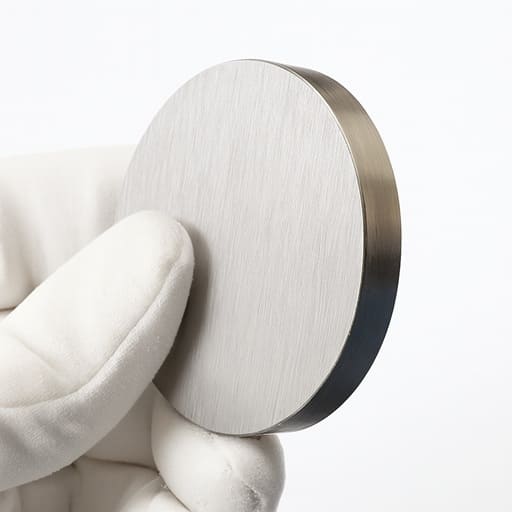

Niobium Sputtering Target

Niobium Sputtering Target

Niobium Sputtering Target is made of high-purity niobium metal material, possessing small grain size. These properties enable the formation of uniform and dense films. As a leading supplier and manufacturer of premium niobium products, Shanghai Yuepeng utilizes advanced machining centers to produce high-precision niobium and niobium alloy sputtering targets for a wide range of applications.

Niobium Sputtering Data Sheet

| Reference: | HMST16 |

| Material: | R04200, R04210 |

| Purity: | 99.5%-99.99% |

| Density: | 8.57 g/cm3 |

| Shape: | Flat, Rotary, or Customized |

| Bonding: | Unbongidng or Bonding |

Niobium Sputtering Target

Niobium is a rare, silvery-gray transition metal with excellent corrosion resistance, electric conductivity, and high-temperature stability. Niobium Sputtering Target can usually reach a purity of more than 99.95% and has a small grain size, which ensures the quality of the coating. Niobium Sputtering Target is commonly applied in semiconductor manufacturing, thin film coatings, electronic components, etc. Shanghai Yuepeng can offer bonding services according to specific requirements.

Niobium Sputtering Target Material Chemical Composition

| Material | Main Element (%) | Impurities (≤%) | ||||||||||||

| Nb | Fe | Si | Ni | W | Mo | Ti | Ta | Zr | Hf | O | C | H | N | |

| RO4200 | Bal. | 0.0040 | 0.0040 | 0.0020 | 0.0050 | 0.0050 | 0.0020 | 0.0700 | 0.0200 | 0.0200 | 0.0150 | 0.0040 | 0.0015 | 0.0030 |

| RO4210 | Bal. | 0.0100 | 0.0100 | 0.0050 | 0.0200 | 0.0100 | 0.0040 | 0.1000 | 0.0200 | 0.0200 | 0.0200 | 0.0100 | 0.0015 | 0.0100 |

Niobium Sputtering Target Specifications

| Material Type | Niobium | Coefficient of Thermal Expansion | 7.3 x 10-6/K |

| Symbol | Nb | Theoretical Density (g/cc) | 8.57 |

| Atomic Weight | 92.90638 | Z Ratio | 0.492 |

| Atomic Number | 41 | Sputter | DC |

| Color/Appearance | Gray, Metallic | Max Power Density (Watts/Square Inch) | 100* |

| Thermal Conductivity | 54 W/m.K | Type of Bond | Indium, Elastomer |

| Melting Point (°C) | 2,468 | Comments | Attacks W source. |

Niobium Sputtering Target Stock Dimensions

| Circular Sputtering Targets | Diameter | 1.0″ 2.0″ 3.0″ 4.0″ 5.0″ 6.0″ up to 21″ |

| Rectangular Sputtering Targets | Width x Length | 5″ x 12″ 5””x 15″ 5″ x 20″ 5″ x 22″ 6″ x 20″ |

| Thickness | 0.125″, 0.25″ | |

Niobium Sputtering Target Production Process

Generally prepared by powder metallurgy method, the purity of niobium powder should be above 99.95%. The specific process is as follows:

- Put the niobium powder in the vacuum heat treatment furnace for pre-gassing, then introduce hydrogen and continue heating for degassing.

- The degassed niobium powder is sintered once by vacuum hot pressing.

- The primary sintered product is then passed through a hot isostatic press to complete the secondary sintering process.

- After secondary sintering, the entire surface of the product is ground by machining to achieve the final product.

Niobium Sputtering Target Applications

- Flat Panel Displays and Liquid Crystal Displays: Niobium sputtering targets are used to manufacture high-quality displays that provide clear images and high contrast.

- Optical Lenses: In optical devices, niobium sputtering targets are used for coating to improve light transmission and durability.

- Solar Cells: Niobium sputtering targets are also used to produce solar cells to improve photovoltaic conversion efficiency.

- Glass Coating: Niobium sputtering targets are used in the surface coating of energy-saving glass with anti-reflective and heat-insulating properties.

Niobium Sputtering Target Packaging

The Niobium Sputtering Target is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Niobium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.