Pyrolytic Boron Nitride Crucible

Pyrolytic Boron Nitride Crucible

Purity: 99.99%-99.999%

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

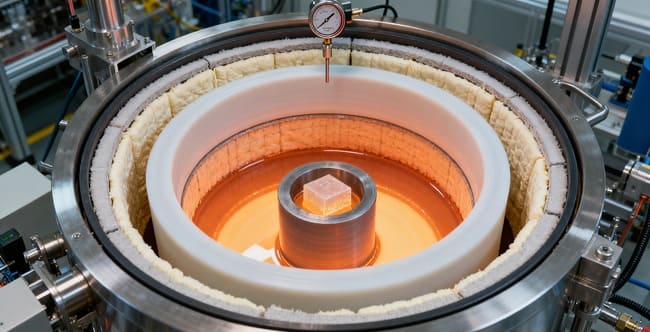

Pyrolytic Boron Nitride Crucible is a high-performance ceramic container with ultra-high purity and excellent high-temperature insulation properties. It is an ideal choice for Molecular Beam Epitaxy (MBE), Liquid Encapsulated Czochralski (LEC), Vertical Gradient Freeze (VGF), or OLED processes. As a leading supplier and manufacturer of premium pyrolytic boron nitride products, Shanghai Yuepeng utilizes advanced machining centers to produce pyrolytic boron nitride crucibles for a wide range of applications.

Pyrolytic Boron Nitride Crucible Data Sheet

| Reference: | PBN1317 |

| Purity: | 99.99%-99.999% |

| Capacity: | PBN OLED Crucible: 300 ml-1200 ml PBN LEC Crucible: 50 ml-5 L PBN MBE Crucible: 5 ml-300 ml PBN VGF Crucible: 0.2 L-5 L |

| Color: | White |

| Density: | 1.95-2.20 g/cm3 |

| Production Method: | CVD |

Pyrolytic Boron Nitride Crucible Description

Pyrolytic Boron Nitride Crucible is a high-purity and high-performance ceramic material. Unlike conventional hot-pressed boron nitride, it is produced through chemical vapor deposition (CVD) under vacuum conditions, using ammonia and boron halides without the need for traditional hot-press sintering or sintering agents. It offers ultra-high purity (up to 99.999%), exceptional high-temperature resistance (up to 2000℃), corrosion resistance, thermal conductivity, and electrical insulation. It is ideal for semiconductor crystal growth, high-temperature melting, and thin film preparation. Shanghai Yuepeng can customize high-quality pyrolytic boron nitride crucibles for various application processes according to specific requirements, including PBN OLED Crucible, PBN MBE Crucible, PBN VGF Crucible, and PBN LEC Crucible.

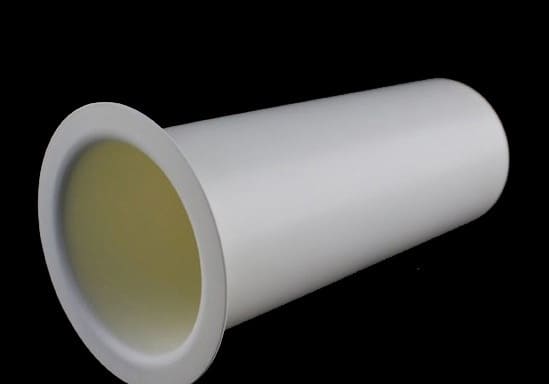

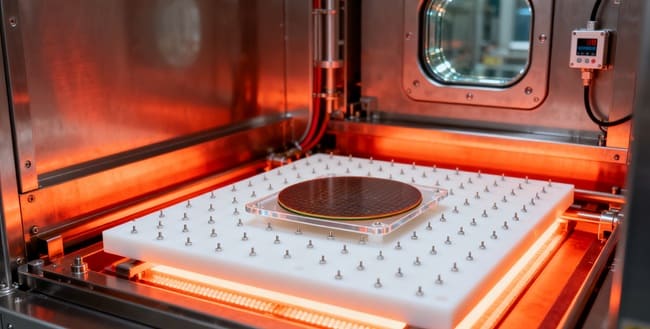

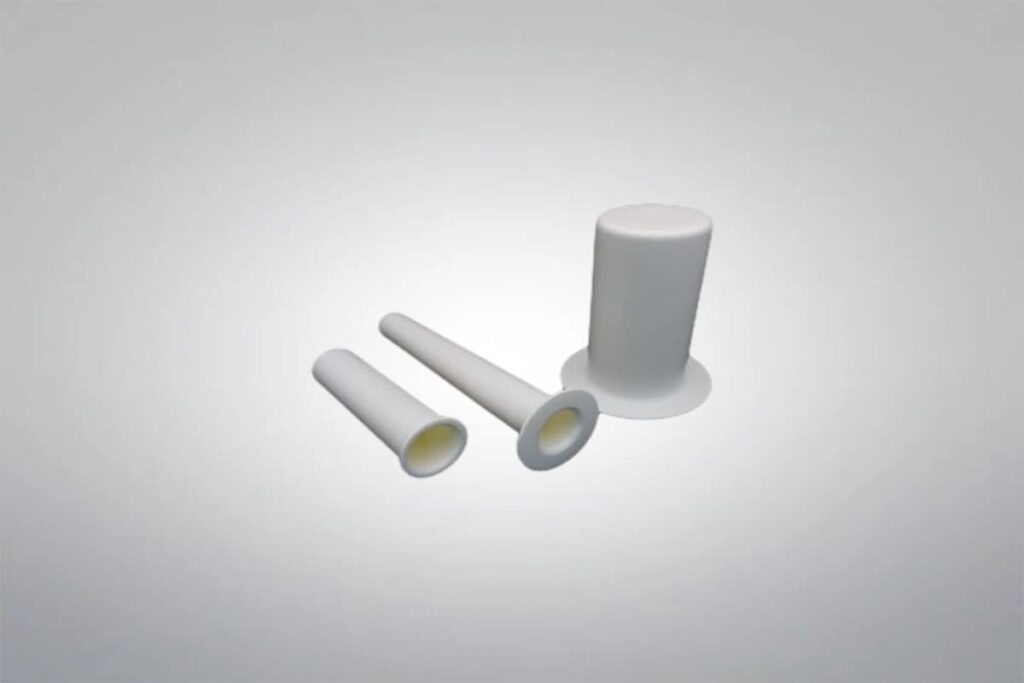

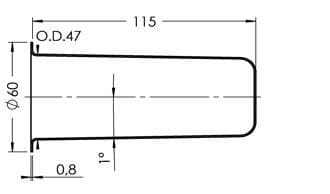

Pyrolytic Boron Nitride OLED Crucible

The PBN OLED Crucible is a type of PBN crucible used in OLED and CIGS vapor deposition technologies. It features ultra-high purity, chemical inertness, excellent high-temperature performance, and thermal stability, making it widely used in metal and semiconductor vapor deposition processes.

- Pyrolytic Boron Nitride OLED Crucible

| Specification | Inner Diameter (mm) | Lip Diameter (mm) | Height (mm) |

| 300cc | 55 | 70 | 160 |

| 500cc | 55 | 82 | 190 |

| 580cc | 62 | 84 | 186 |

| 700cc | 61 | 85 | 240 |

| 1200cc | 78 | 115 | 240 |

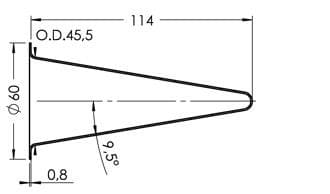

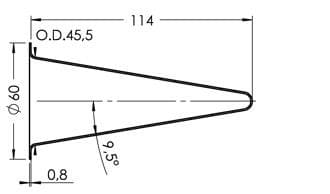

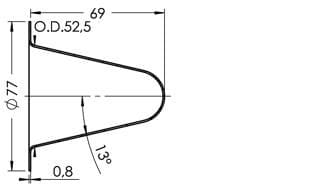

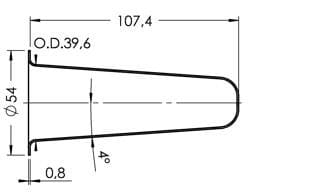

Pyrolytic Boron Nitride MBE Crucible

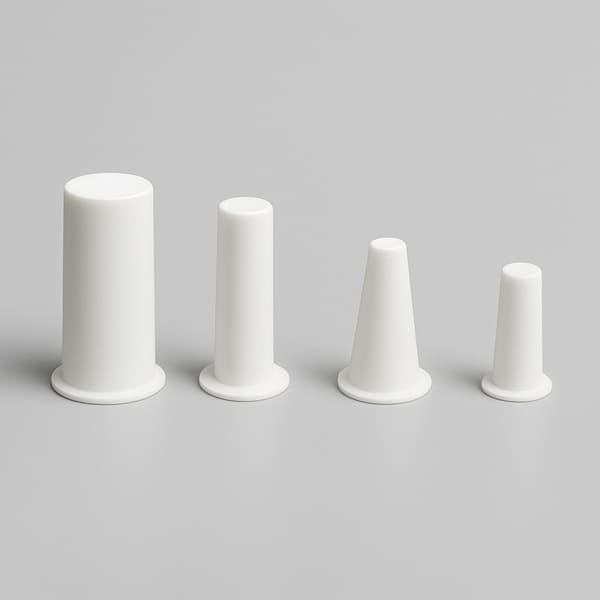

The PBN MBE Crucible is a high-performance crucible used in the Molecular Beam Epitaxy (MBE) process. It features ultra-high purity, chemical inertness, and excellent high-temperature stability, allowing it to withstand high temperatures during the MBE process without releasing gases or undergoing chemical reactions.

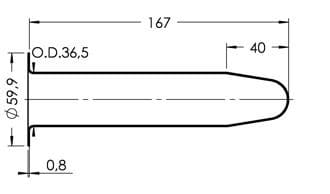

- Pyrolytic Boron Nitride MBE Crucible

| MBE equipment | Specification | Inner Diameter (mm) | Lip Diameter (mm) | Height (mm) |

| Veeco | 125cc | 37 | >55 | 118 |

| Veeco | 500cc | 100 | 130 | 160 |

| Veeco | 1700cc | 130 | 160 | 290 |

| Veeco | 3700cc | 180 | 210 | 300 |

| Riber | BN-100L | 13 | 27 | 77 |

| Riber | BN-125L | 20 | 32 | 89 |

| Riber | BN-135L | 24 | 37 | 89 |

| Riber | 200cc | 68 | 84 | 156 |

| Note | The dimensions and shapes can be customized according to specific requirements. | |||

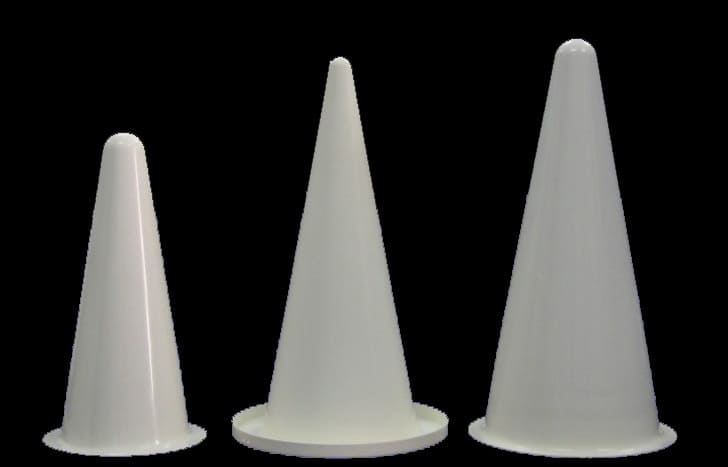

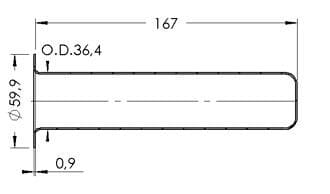

Pyrolytic Boron Nitride VGF Crucible

The VGF crucible is a container used in the Vertical Gradient Freezing (VGF) technique for synthesizing crystals such as GaAs, InP, CZGaP, and Ge. PBN VGF crucibles can withstand high temperatures and provide a stable thermal environment, allowing the crystal to grow in a controlled manner from the bottom upwards. This results in single crystals with low defect density and high uniformity.

| Catalog No | Application | Inside Diameter | Height | Thickness |

| BV-2 | VGF | 2″ | 10″ | 0.035″ |

| BV-3 | VGF | 3″ | 10″ | 0.035″ |

| BV-4 | V | 4″ | 8″ | 0.035″ |

| BV-5 | VGF | 5″ | 8″ | 0.04″ |

| BV-6 | VGF | 6″ | 7″ | 0.04″ |

| BV-8 | VGF | 8″ | 20″ | 0.08″ |

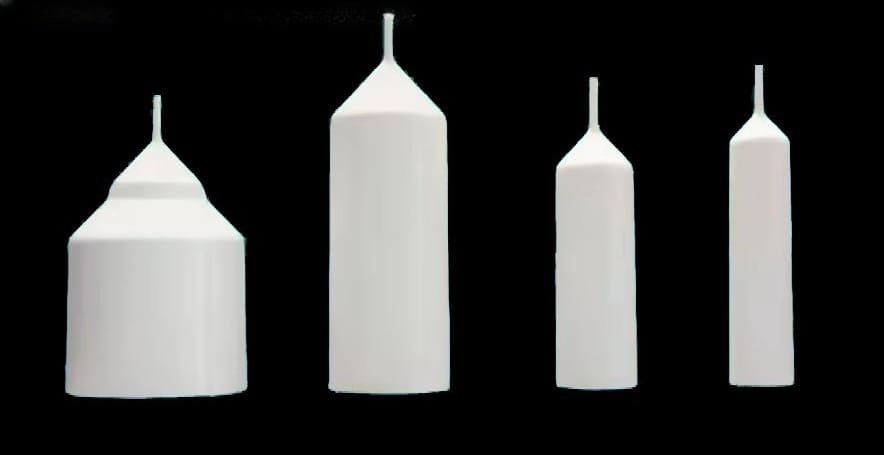

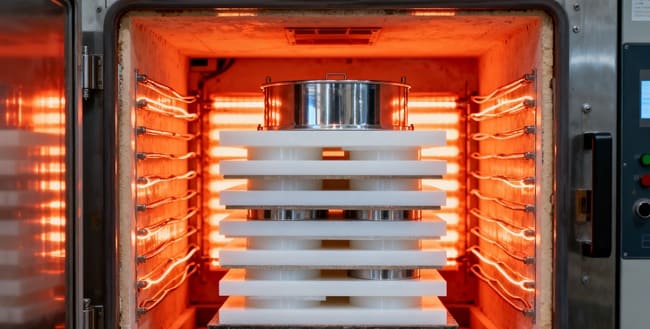

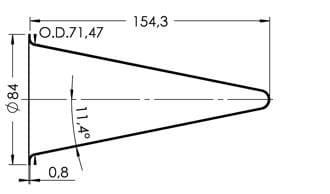

Pyrolytic Boron Nitride LEC Crucible

The PBN LEC crucible is a high-performance ceramic container specifically designed for the Liquid Encapsulated Czochralski (LEC) method, primarily used for growing compound semiconductor single crystals such as Gallium Arsenide (GaAs) and Indium Phosphide (InP). The exceptional chemical stability and corrosion resistance of the PBN LEC crucible ensure that it is not eroded by the melt or encapsulants while supporting the slow extraction of the crystal from the melt to form high-quality single crystals.

- Pyrolytic Boron Nitride LEC Crucible

| Catalog No | Application | Inside Diameter | Height | Thickness |

| BL-3 | LEC | 3″ | 3″ | 0.03″ |

| BL-4 | LEC | 4″ | 4″ | 0.035″ |

| BL-5 | LEC | 5″ | 5″ | 0.035″ |

| BL-6 | LEC | 6″ | 6″ | 0.04″ |

| BL-7 | LEC | 7″ | 7″ | 0.04″ |

| BL-8 | LEC | 8″ | 8″ | 0.04″ |

| BL-14 | LEC | 14″ | 14″ | 0.08″ |

Pyrolytic Boron Nitride Crucible Available Specifications

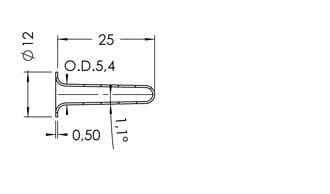

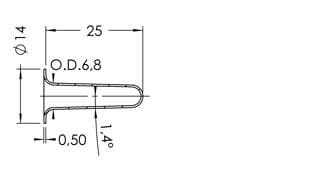

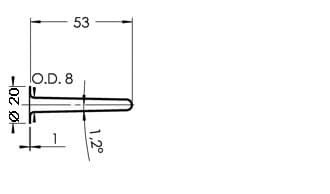

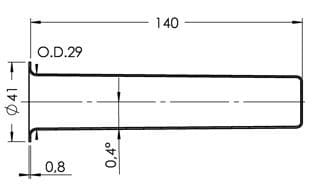

|  |  |  |

| Code: PBN-C1-12 Capacity:1 cm³ | Code: PBN-C1-14 Capacity:1 cm³ | Code: PBN-C1-20 Capacity: 1.5 cm³ | Code: PBN-C2-16 Capacity: 2cm³ |

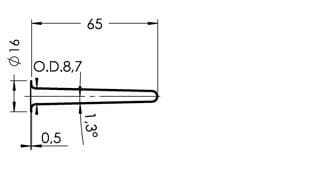

|  |  |  |

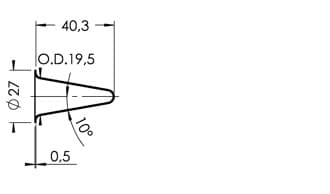

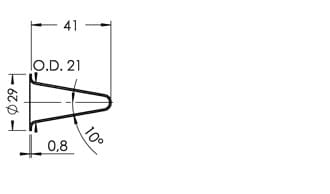

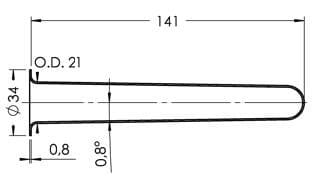

| Code: PBN-C2-22 Capacity: 2 cm³ | Code: PBN-C5-16 Capacity: 5 cm³ | Code: PBN-C5-27 Capacity: 5 cm³ | Code: PBN-C5-29 Capacity:5 cm³ |

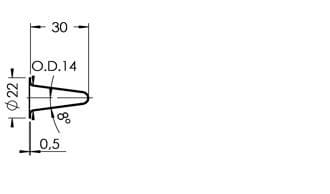

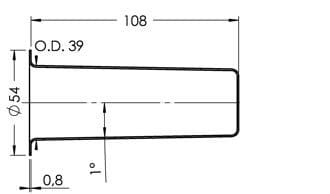

|  |  |  |

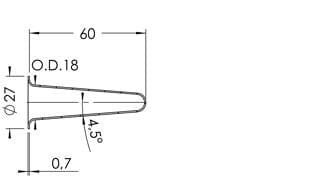

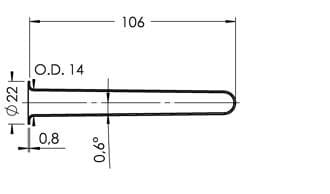

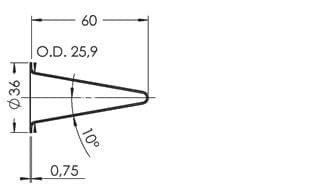

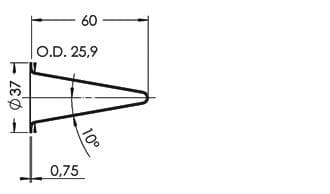

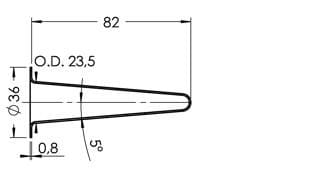

| Code: PBN-C8-27 Capacity: 8 cm³ | Code: PBN-C10-22 Capacity: 10 cm³ | Code: PBN-C12-36 Capacity: 12 cm³ | Code: PB-C12-37 Capacity: 12 cm³ |

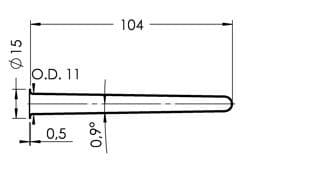

|  |  |  |

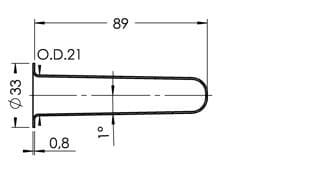

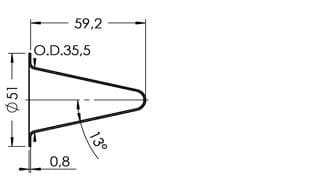

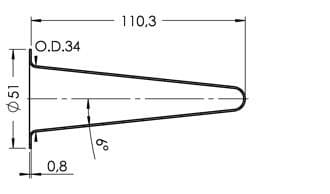

| Code: PBN-C16-36 Capacity: 16 cm³ | Code: PBN-C25-33 Capacity: 25 cm³ | Code: PBN-C25-51 Capacity: 25 cm³ | Code: PBN-C35-34 Capacity: 35 cm³ |

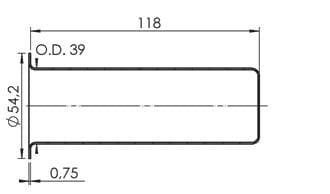

|  |  |  |

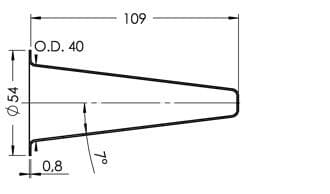

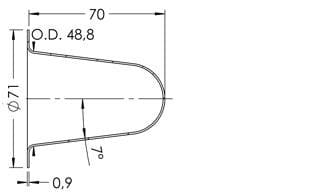

| Code: PBN-C40-51 Capacity: 40 cm³ | Code: PBN-C60-54 Capacity: 60 cm³ | Code: PBN-C60-37 Capacity: 60cm³ | Code: PBN-C70-60 Capacity: 70 cm³ |

|  |  |  |

| Code: PBN-C75-77 Capacity: 75 cm³ | Code: PBN-C80-54 Capacity: 80 cm³ | Code: PBN-C82-71 Capacity: 82 cm³ | Code: PBN-C85-41 Capacity: 85 cm³ |

|  |  |  |

| Code: PBN-C125-54 Capacity: 125 cm³ | Code: PBN-C130-54 Capacity: 130 cm³ | Code: PBN-C150-60 Capacity: 150 cm³ | Code: PBN-C155-60 Capacity: 155 cm³ |

|  |  |  |

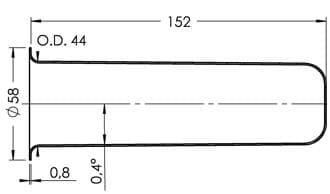

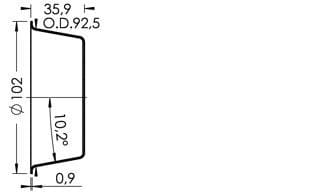

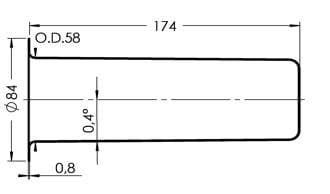

| Code: PBN-C160-60 Capacity: 160 cm³ | Code: PBN-C200-84 Capacity : 200 cm³ | Code: PBN-C200-58 Capacity: 200 cm³ | Code: PBN-C200-102 Capacity: 200 cm³ |

| |||

| Code: PBN-C420-84 Capacity : 420 cm³ |

Pyrolytic Boron Nitride Crucible Advantages

- High purity (99.99%-99.999%)

- High density (>2.12 g/cm³)

- No gas release at high temperatures

- Uniform thickness, excellent heating consistency

- Outstanding thermal conductivity and thermal shock resistance

- High interlayer strength, easy to clean, reusable

- Chemically inert, does not react with acids, alkalis, salts, or organic solvents at high temperatures

Pyrolytic Boron Nitride Crucible Applications

- Crystal Growth: Widely used in the growth of compound semiconductors such as GaAs, InP, and GaN, due to its high purity and non-reactive nature.

- Vacuum Evaporation: Serves as a stable container for evaporation of metals and semiconductors in high-vacuum environments.

- High-Temperature Materials Processing: Applied in metallurgy and advanced ceramics for melting, sintering, and high-temperature reaction studies.

- Semiconductor Manufacturing: Utilized in thin-film deposition and epitaxial growth processes where contamination-free performance is critical.

- Optoelectronic Applications: Provides a reliable vessel for producing LED, laser diode, and photovoltaic materials that require precise and clean processing conditions.

- Crystal growth

- Semiconductor processing

- Semiconductor Industry

- High-Temperature Furnaces

- Optoelectronics

Pyrolytic Boron Nitride Material Properties

Pyrolytic Boron Nitride Machining

Shanghai Yuepeng is equipped with multiple CNC lathes and CNC milling machines, and it is backed by extensive machining experience. We offer customized pyrolytic boron nitride ceramic products and profiles with extremely tight tolerances, tailored to customer requirements. During the machining process, the following precautions should be observed:

- Pyrolytic boron nitride ceramic materials can be machined using standard high-speed steel cutting tools. For harder and composite materials, carbide or diamond tools are recommended.

- Grinding operations can be performed as needed, and standard taps and dies can be used to machine threads.

- The machining process should always be kept dry, with no need for cutting oils or coolants.

- Cutting tools should be sharp and clean, and tools with negative rake angles should not be used.

- Care should be taken when clamping and securing materials to avoid applying excessive pressure. Climb milling techniques should be used to prevent edge and corner chipping.

Pyrolytic Boron Nitride Packaging

Pyrolytic Boron Nitride Ceramic products are carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.