Pyrolytic Boron Nitride Tube

Pyrolytic Boron Nitride Tube

Purity: 99.99%-99.999%

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

Pyrolytic Boron Nitride Tube is a high-performance ceramic component made through chemical vapor deposition (CVD). It has an ultra-high purity of up to 99.999%. As a leading supplier and manufacturer of premium pyrolytic boron nitride products, Shanghai Yuepeng utilizes advanced machining centers to produce pyrolytic boron nitride tubes for a wide range of applications.

Pyrolytic Boron Nitride Tube Data Sheet

| Purity: | 99.99%-99.999% |

| Color: | White |

| Density: | 1.95-2.20 g/cm3 |

| Production Method: | CVD |

Pyrolytic Boron Nitride Tube Description

Pyrolytic Boron Nitride Tube is a high-purity and high-performance ceramic material. Unlike conventional hot-pressed boron nitride, it is produced through chemical vapor deposition (CVD) under vacuum conditions, using ammonia and boron halides without the need for traditional hot-press sintering or sintering agents. It offers exceptional high-temperature resistance (up to 2000℃), corrosion resistance, and electrical insulation. With a purity exceeding 99.99%, virtually free of impurities, and a smooth, pore-free surface, the PBN tube is ideal for applications in high-vacuum or inert atmospheres. Shanghai Yuepeng can supply customized solutions for diameter, length, wall thickness, and surface finishes to meet specific requirements.

Pyrolytic Boron Nitride Tube Advantages

- Non-toxic, odorless.

- High purity, exceeding 99.999%.

- Do not react with acids, alkalis, salts, or organic reagents at room temperature; it slightly corrodes in molten salt or alkali solutions but is resistant to corrosion by most acids at high temperatures.

- Do not react with most molten metals, semiconductors, or their compounds.

- Exhibits good oxidation resistance below 1000°C.

- Excellent thermal shock resistance, with no cracks observed when immersed in water at 2000°C.

- High operating temperature with no sublimation point; decomposes directly into B and N above 3000°C.

- High electrical resistance and good electrical insulation properties.

- Smooth surface with no pores, does not wet most semiconductor melts.

Pyrolytic Boron Nitride Tube Applications

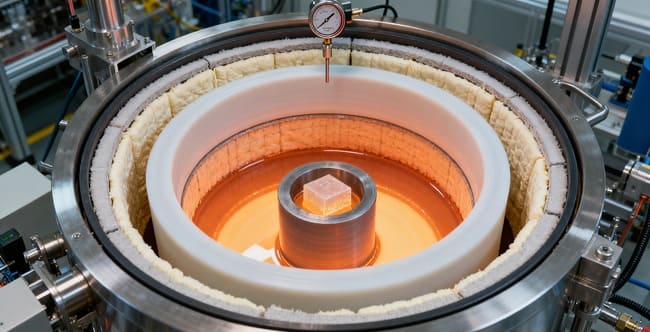

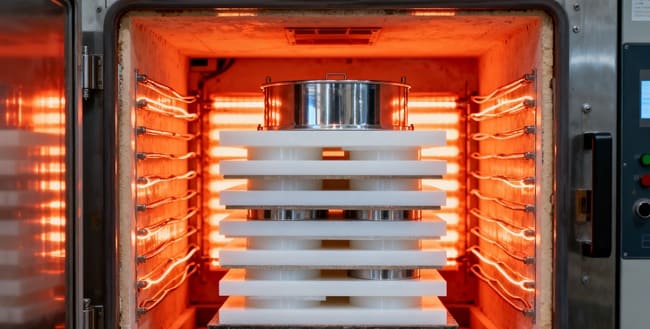

- High-Temperature Furnaces: PBN tubes are used as protective liners or structural parts in furnaces, providing thermal stability and resistance to cracking under extreme heat.

- Crystal Growth Processes: They act as containers or insulation parts in crystal growth equipment, ensuring ultra-clean and stable environments for single-crystal materials.

- Vacuum Technology: PBN tubes are applied in vacuum systems where low outgassing and chemical inertness are essential for maintaining purity.

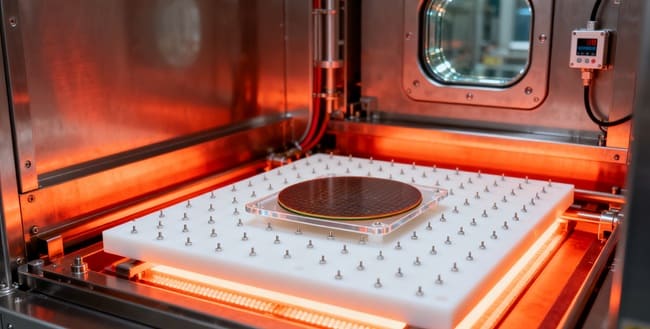

- Semiconductor Manufacturing: They serve as components in semiconductor equipment, offering electrical insulation and resistance to contamination during high-temperature processes.

- Chemical and Metallurgical Applications: PBN tubes are used for handling molten metals, reactive chemicals, and corrosive environments where other materials would degrade.

- Crystal growth

- Semiconductor processing

- Semiconductor Industry

- High-Temperature Furnaces

- Metallurgy and Foundry

Pyrolytic Boron Nitride Material Properties

Pyrolytic Boron Nitride Machining

Shanghai Yuepeng is equipped with multiple CNC lathes and CNC milling machines, and it is backed by extensive machining experience. We offer customized pyrolytic boron nitride ceramic products and profiles with extremely tight tolerances, tailored to customer requirements. During the machining process, the following precautions should be observed:

- Pyrolytic boron nitride ceramic materials can be machined using standard high-speed steel cutting tools. For harder and composite materials, carbide or diamond tools are recommended.

- Grinding operations can be performed as needed, and standard taps and dies can be used to machine threads.

- The machining process should always be kept dry, with no need for cutting oils or coolants.

- Cutting tools should be sharp and clean, and tools with negative rake angles should not be used.

- Care should be taken when clamping and securing materials to avoid applying excessive pressure. Climb milling techniques should be used to prevent edge and corner chipping.

Pyrolytic Boron Nitride Packaging

Pyrolytic Boron Nitride Ceramic products are carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.