Quartz Crucible

Quartz Crucible

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

Quartz Crucible are made from high-purity fused silica ceramic with fine microstructure, offering low thermal conductivity, minimal thermal expansion, and high dimensional precision. They maintain shape and strength under extreme heat and exhibit outstanding thermal shock resistance. These properties make quartz crucibles reliable for demanding applications in the glass processing industry, electronics manufacturing, metallurgy, and aerospace. Their strong chemical resistance and electrical insulation further expand their utility in harsh environments where purity and stability are critical. As a leading supplier and manufacturer of premium quartz products, Shanghai Yuepeng can supply high-quality quartz crucibles with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Quartz Crucible Data Sheet

| Color: | White |

| Shape: | Cylinder, Conical Cylinder, Rectangular, T-shape, or customized. |

| Dimension: | Customized |

| Chemical Formula: | SiO2 |

| Compressive Strength: | ≥ 50 MPa |

| Thermal Expansion Coefficient: | ≤ 0.6 |

| Maximum Temperature (℃): | 1650 ℃ |

| Long-Term Operating Temperature (℃): | 1100 ℃ |

Quartz Crucible Description

Quartz crucible plays a vital role in the solar energy industry, especially in the production of polysilicon for photovoltaic applications. With the rapid growth of solar power, the demand for large, thin-walled square and round crucibles has increased. Thanks to its outstanding thermal stability, resistance to molten silicon and metals like aluminum and copper, and non-contaminating nature, the quartz crucible is widely used in polysilicon processing and non-ferrous metal smelting, offering both purity and durability under extreme conditions.

Quartz Crucible Specifications

| Shape | Dimensions (mm) |

|---|---|

| Square | 1100 × 1100 × 550 |

| Square | 878 × 878 × 480 |

| Square | 878 × 878 × 420 |

| Square | 720 × 720 × 420 |

| Square | 585 × 585 × 420 |

| Square | 440 × 440 × 350 |

| Square | 220 × 220 × 95 |

| Round | Φ610 × 420 |

| Round | Φ100 × 300 |

| Customized | Custom dimensions available |

Quartz Crucible Features

- excellent thermal stability with minimal deformation at high temperatures.

- A low thermal expansion coefficient reduces the risk of cracking during rapid temperature changes.

- High-purity fused silica material ensures minimal contamination.

- Strong resistance to chemical corrosion from molten silicon, metals, and acids.

- Available in both round and square shapes for different industrial needs.

Quartz Crucible Applications

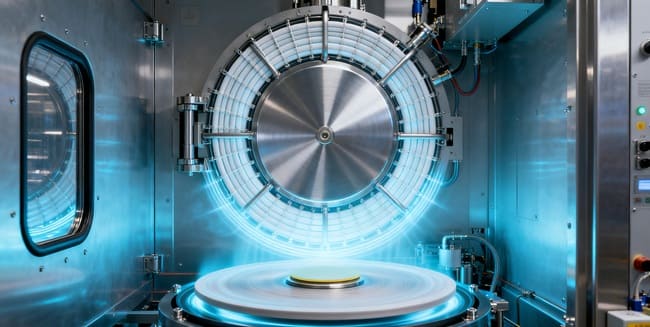

- Semiconductor Manufacturing: Quartz crucibles are essential for growing single-crystal silicon in the Czochralski (CZ) process, providing high purity and excellent thermal stability required for chip production.

- Glass and Metal Melting: They are used for melting high-purity glass, precious metals, and alloys due to their strong heat resistance and minimal contamination.

- Laboratory Chemical Analysis: Quartz crucibles are applied in high-temperature chemical reactions and ash content determination, ensuring accurate results with minimal reactivity.

- Optical Material Processing: They serve in the preparation and purification of optical materials, maintaining clarity and chemical purity throughout the heating process.

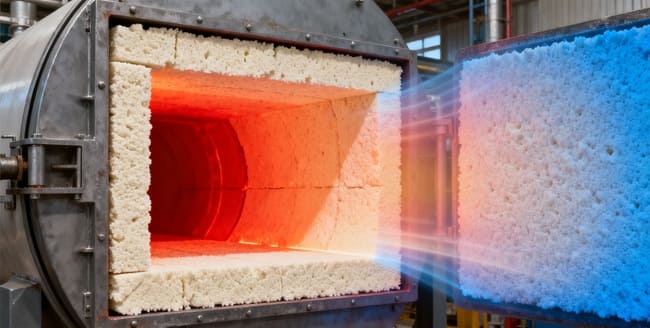

- Thermal Treatment and Annealing: Quartz crucibles are used in furnaces and annealing systems for heat treatment of materials that require clean, stable, and high-temperature environments.

- Laboratory Equipment

- Semiconductor Manufacturing

- Glass Forming

- Optical and electronic industries

- Thermal Insulation

Quartz Ceramic Material Properties

| Purity (%) | >99.8 | >99.5 |

| Density (g/cm3) | 1.9-1.95 | 1.9-1.95 |

| Flexture strength (MPa) | 28 | 28 |

| Compressive strength (MPa) | >50 | >50 |

| Bending strength (MPa) | 25 | 25 |

| Maximum working temperature (℃) | 1650 | 1650 |

| Thermal conductivity (W/m*K) | <1 | <1 |

| Thermal expansion coefficient (/℃) | 8.5*10-7 | 8.5*10-7 |

| number of use | ≥10 | ≥10 |

Quartz Ceramic Material Machining

Quartz ceramic material can be machined in its green or bisque state before sintering, making it easier to shape into complex forms. Like other ceramics, it shrinks by about 15–20% during sintering, so this must be considered in the initial design. After sintering, quartz ceramic becomes extremely hard and brittle, making machining very difficult and requiring diamond-coated tools and high-precision equipment.

Machining Methods and Considerations

- Green or Bisque Machining: Quartz ceramic is easier to cut and shape before sintering, making it suitable for intricate designs.

- Sintering Shrinkage: Expect a 15–20% size reduction during sintering, which affects dimensional accuracy.

- Post-Sintering Machining: After sintering, quartz becomes hard and brittle, requiring diamond tools and precise control.

- Fragility: Fully sintered quartz ceramic is prone to chipping or cracking if mishandled.

- Tooling and Time: Machining sintered quartz is slow and requires specialized equipment.

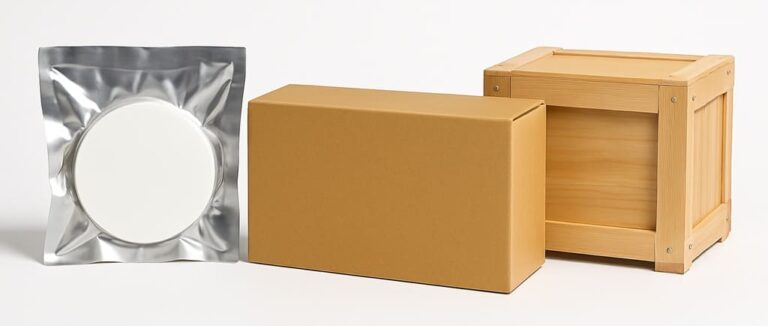

Quartz Ceramic Packaging

Quartz ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of the products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.