Tantalum Powder

Tantalum Powder

Tantalum Powder has excellent thermal and electrical conductivity, making it ideal for optics and electronics. As a leading supplier and manufacturer of premium tantalum products, Shanghai Yuepeng utilizes advanced machining centers to produce high-quality tantalum and tantalum alloy powder products for a wide range of applications.

Tantalum Powder Data Sheet

| Reference: | HMTA0002 |

| Molecular Formula: | Ta |

| CAS: | 7440-25-7 |

| Purity: | 99%, 99.9%, 99.95%, 99.99%, 99.999% |

| Particle Size: | -325 mesh, -200 mesh, or customized |

Tantalum Powder

Tantalum Powder is a high-purity tantalum metal powder known for its high melting point, excellent corrosion resistance, and good electrical conductivity. It is widely used in electronics, aerospace, and medical industries, commonly for manufacturing capacitors, alloy additives, or 3D printing materials. Its fine particles and high chemical stability make it ideal for high-performance applications.

Tantalum Powder Specifications

| Category | 4N Tantalum Powder | 3N5 Tantalum Powder | |||||||

| Grade | FT-01 | FT-02 | FT-03 | FT-04 | FT-1 | FT-2 | FT-3 | FT-4 | |

| Impurity content (≤%) | Nb | 0.0030 | 0.0030 | 0.0030 | 0.0030 | 0.0060 | 0.0060 | 0.0060 | 0.0060 |

| O | 0.0800 | 0.0900 | 0.1000 | 0.1600 | 0.0850 | 0.0950 | 0.1100 | 0.1800 | |

| N | 0.0030 | 0.0030 | 0.0030 | 0.0030 | 0.0050 | 0.0050 | 0.0050 | 0.0050 | |

| C | 0.0020 | 0.0020 | 0.0020 | 0.0020 | 0.0050 | 0.0050 | 0.0050 | 0.0050 | |

| Fe | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0030 | 0.0030 | 0.0030 | 0.0030 | |

| Si | 0.0020 | 0.0020 | 0.0020 | 0.0020 | 0.0020 | 0.0020 | 0.0020 | 0.0020 | |

| Ni | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0020 | 0.0020 | 0.0020 | 0.0020 | |

| Cr | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0020 | 0.0020 | 0.0020 | 0.0020 | |

| W | 0.0010 | 0.0010 | 0.0010 | 0.0010 | 0.0020 | 0.0020 | 0.0020 | 0.0020 | |

| Mo | 0.0010 | 0.0010 | 0.0010 | 0.0010 | 0.0010 | 0.0010 | 0.0010 | 0.0010 | |

| Ti | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

| Mn | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

| Cu | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

| Al | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

| Screening | -100 mesh | -200 mesh | -300 mesh | -500 mesh | -100 mesh | -200 mesh | -300 mesh | -500 mesh | |

| Oversized material is less than 5% | Oversized material is less than 5% | ||||||||

Low Oxygen Tantalum Powder Specifications

| Category | Low Oxygen Tantalum Powder | ||||

| Grade | FTD-01 | FTD-02 | FTD-03 | FTD-04 | |

| Impurity Content (≤%) | Nb | 0.0060 | 0.0060 | 0.0060 | 0.0060 |

| O | 0.0200 | 0.0300 | 0.0400 | 0.0500 | |

| N | 0.0050 | 0.0050 | 0.0050 | 0.0050 | |

| C | 0.0050 | 0.0050 | 0.0050 | 0.0050 | |

| Fe | 0.0030 | 0.0030 | 0.0030 | 0.0030 | |

| Si | 0.0020 | 0.0020 | 0.0020 | 0.0020 | |

| Ni | 0.0020 | 0.0020 | 0.0020 | 0.0020 | |

| Cr | 0.0020 | 0.0020 | 0.0020 | 0.0020 | |

| W | 0.0020 | 0.0020 | 0.0020 | 0.0020 | |

| Mo | 0.0010 | 0.0010 | 0.0010 | 0.0010 | |

| Ti | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

| Mn | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

| Cu | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

| Al | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

| Screening | -100 mesh | -200 mesh | -300 mesh | -500 mesh | |

| Oversized material is less than 5% | |||||

Tantalum Powder Properties

- High purity

- Low oxygen content

- Large specific surface area

- Uniform particle size distribution

- Good flowability

- High specific capacitance

- Low leakage current

Tantalum Powder Applications

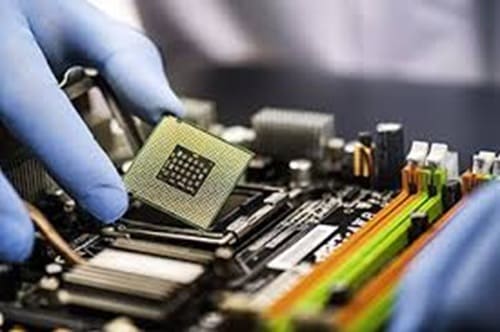

- Electronics: Tantalum powder is widely used to manufacture tantalum capacitors, which are applied in communication equipment, computers, automobile electronics, household applications, etc.

- Superalloys: Tantalum powder’s high strength and high-temperature resistance allow it to be used to manufacture superalloys for aerospace and nuclear energy applications.

- Chemical industry: Tantalum powder is commonly used to manufacture chemical reaction vessels and pipelines that handle strong corrosive media.

- Medical: Porous tantalum materials, made from tantalum powder, exhibit excellent biocompatibility and mechanical properties, and are commonly used for treating bone tissue injuries and femoral necrosis.

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

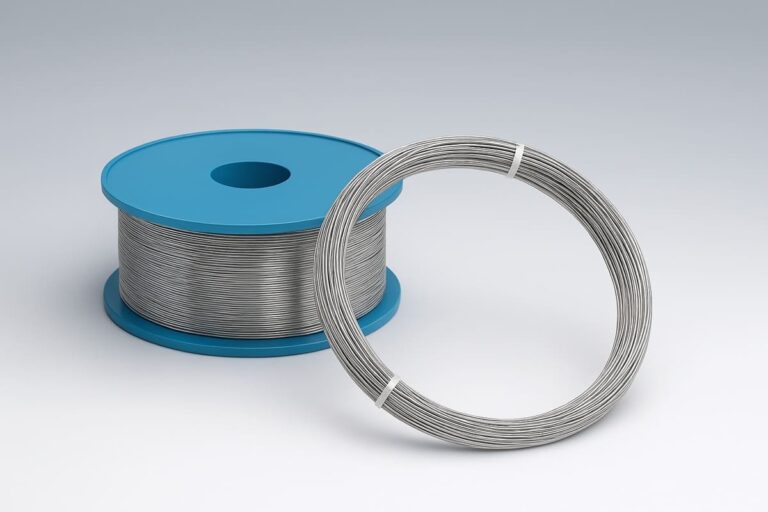

Tantalum Powder Packaging

The tantalum powder will be carefully handled to prevent damage during storage and transportation. Shanghai Yuepeng offers vacuum-sealed packaging, including 100g/bag, 500g/bag, 1kg/bag, and 25kg/drum, or can offer customized packaging as per specific requirements.

Tantalum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.