Tantalum Sputtering Target

Tantalum Sputtering Target

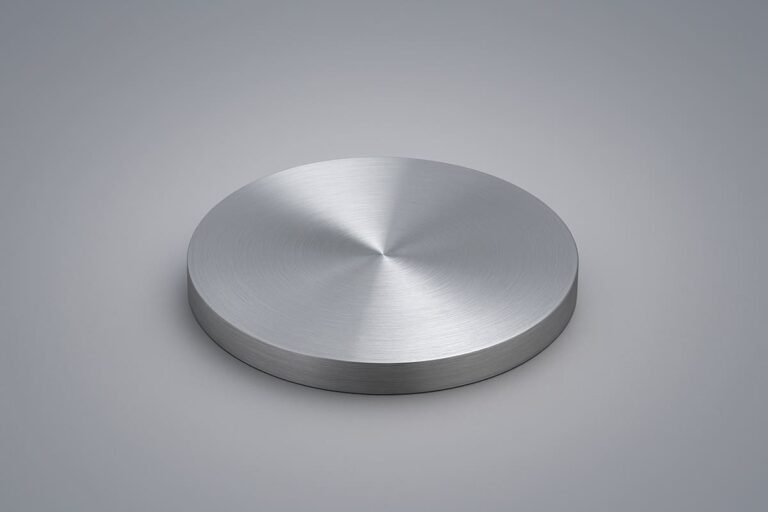

Tantalum Sputtering Target is made from high-purity tantalum material through pressure processing, offering high chemical purity, fine grain size, good recrystallized structure, and excellent consistency along all three axes. As a leading supplier and manufacturer of premium tantalum products, Shanghai Yuepeng utilizes advanced machining centers to produce high-precision tantalum and tantalum alloy sputtering targets for a wide range of applications.

Tantalum Sputtering Target Data Sheet

| Reference: | HMST22 |

| Dimensions: | Thickness: 0.125″-0.25″ Circular Sputtering Targets: 1.0″-21″ (diameter), or customized Rectangular Sputtering Targets: 5″×12″, 5″×15″, 5″×20″, 5″×22″, 6″×20″, or customized |

| Material: | R05200, R05400 |

| Purity: | 99.9%, 99.95%, 99.99%, 99.999% |

| Forms: | Flat Target, Rotary Target, or Custom Shapes |

| Bonding: | Bonding or Unbonding |

Tantalum Sputtering Target

Tantalum Sputtering Target is a high-purity tantalum metal material used in physical vapor deposition (PVD) processes to create thin film coatings. Known for its high melting point, corrosion resistance, and excellent conductivity, tantalum targets are widely applied in semiconductors, solar cells, flat-panel displays, and optical coatings. Their high purity and uniform microstructure ensure stable and reliable film quality.

Tantalum (Ta) Specifications

Tantalum is classified as a transition metal on the Periodic Table and is considered one of the refractory metals highly resistant to corrosion. Due to its excellent corrosion resistance and thermal stability, tantalum is widely used in electronics, aerospace, and chemical engineering, particularly in manufacturing electronic components, chemical reactors, and semiconductors.

| Material Type | Tantalum | Coefficient of Thermal Expansion | 6.3 x 10-6/K |

| Symbol | Ta | Theoretical Density (g/cc) | 16.6 |

| Atomic Weight | 180.94788 | Z Ratio | 0.262 |

| Atomic Number | 73 | Sputter | DC |

| Color/Appearance | Gray Blue, Metallic | Max Power Density (Watts/Square Inch) | 50* |

| Thermal Conductivity | 57 W/m.K | Type of Bond | Indium, Elastomer |

| Melting Point (°C) | 3,017 | Comments | Forms good films. |

Tantalum Sputtering Target Stock Dimensions

Tantalum sputtering targets are manufactured to precise tolerances to meet specific application requirements. Shanghai Yuepeng also offers bonding services, with the ability to customize dimensions and shapes based on customer specifications. The regular dimensions are as follows:

| Circular Sputtering Targets | Diameter | 1.0” 2.0” 3.0” 4.0” 5.0” 6.0” up to 21” |

| Rectangular Sputtering Targets | Width x Length | 5” x 12” 5” x 15” 5” x 20” 5” x 22” 6” x 20” |

| Thickness | 0.125”, 0.25” | |

Tantalum Sputtering Target Material Chemical Composition

| Element | R05200 (%, Max) | R05400 (%, Max) |

| C | 0.01 | 0.01 |

| O | 0.015 | 0.03 |

| N | 0.01 | 0.01 |

| H | 0.0015 | 0.0015 |

| Fe | 0.01 | 0.01 |

| Mo | 0.02 | 0.02 |

| Nb | 0.1 | 0.1 |

| Ni | 0.01 | 0.01 |

| Si | 0.005 | 0.005 |

| Ti | 0.01 | 0.01 |

| W | 0.05 | 0.05 |

Tantalum Sputtering Target Manufacturing Process

The manufacturing process involves sintering high-purity tantalum powder into blocks and melting them into ingots via a high-vacuum electron beam. These ingots undergo repeated plastic deformation and annealing to produce target blanks with uniform grain structure, which are then welded to backplates and machined into the final product for semiconductor sputtering. Here is the typical production process:

- Sintering

- Vacuum Electron Beam Melting

- Plastic Deformation

- Annealing

- Metallographic Inspection

- Machining

- Dimensional Inspection

- Cleaning

- Final Inspection

Tantalum Sputtering Target Applications

The tantalum sputtering target, often called a bare target, is first soldered to a copper backing plate. It is then used in semiconductor or optical sputtering processes, where tantalum atoms are deposited as oxides onto a substrate to form a sputter coating. The main applications include:

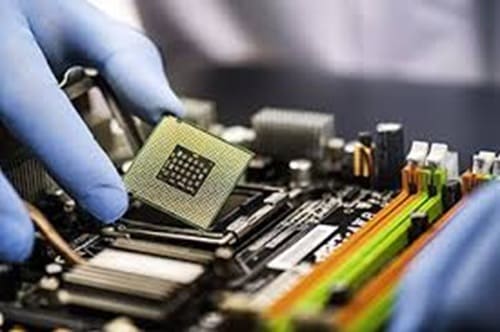

- Electronics and Semiconductors: Tantalum targets are widely used as barrier layers in integrated circuit (IC) manufacturing, particularly in copper interconnect technology. Tantalum’s high melting point and low resistance make it an ideal choice for these applications.

- Anti-Corrosion Coatings: Due to its exceptional corrosion resistance, tantalum is frequently used to coat chemical equipment and metal surfaces exposed to harsh environments, helping to extend the service life of these materials.

- Thin Films for Optics and Photonics: Tantalum targets are employed to create thin films with specific optical properties for use in various optical devices, displays, and sensors.

- Medical Devices: With its excellent biocompatibility, tantalum is used to coat medical implants such as bone plates and joint prostheses, reducing the risk of rejection by the body.

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Tantalum Sputtering Target Packaging

The Tantalum Sputtering Target is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Tantalum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.