Tantalum Tungsten Alloy Powder

Tantalum Tungsten Alloy Powder

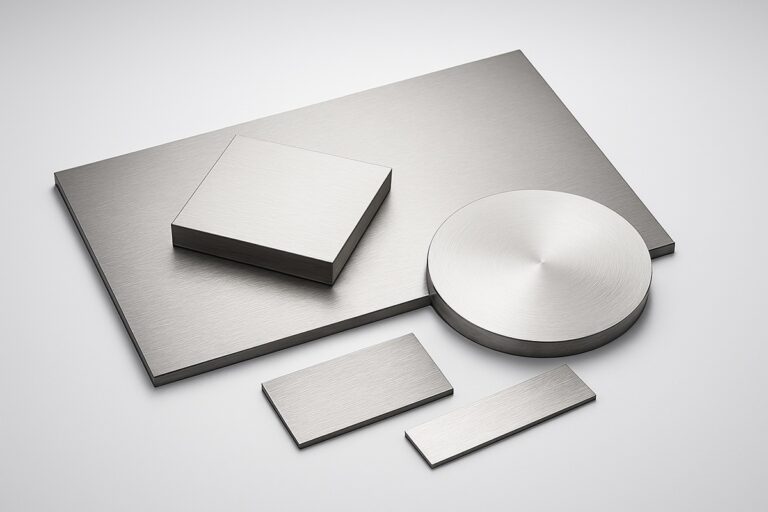

Tantalum Tungsten Alloy Powder is a high-performance metal material made from tantalum and tungsten in precise proportions. The regular compositions include Ta-2.5W, Ta-5.5W, Ta-7.5W, and Ta-10W. The composition ratio can be customized according to specific requirements. As a leading supplier and manufacturer of premium tantalum products, Shanghai Yuepeng utilizes advanced machining centers to produce high-quality tantalum tungsten alloy powder for a wide range of applications.

Tantalum Tungsten Alloy Powder Data Sheet

| Purity: | 99.5%, 99.9%, 99.95% |

| Material: | Ta-2.5W, Ta-5.5W, Ta-7.5W, Ta-10W, or customized |

| Particle Size: | -200 mesh or customized |

| Morphology: | Irregular or Spherical |

Tantalum Tungsten Alloy Powder

Tantalum Tungsten Alloy Powder, made from precise tantalum and tungsten ratios, includes Ta-2.5W, Ta-5.5W, Ta-7.5W, Ta-10W, or custom blends. It offers excellent high-temperature resistance, corrosion resistance, and strength, ideal for 3D printing, coatings, and precision components. To meet diverse application requirements, we have also developed a comprehensive range of high-performance powder products, including high-purity tantalum powder, low-oxygen tantalum powder (oxygen content as low as 200ppm), low-oxygen niobium powder (oxygen content as low as 400ppm), C103 niobium alloy powder, Nb521 niobium alloy powder, etc. Shanghai Yuepeng can offer high-quality tantalum tungsten alloy powder in various particle sizes, customized to meet the specific requirements of multiple applications.

Tantalum Tungsten Alloy Powder Specifications-Low Oxygen

| Category | Low-oxygen Tantalum Tungsten Alloy Powder | ||||

| Grade | Ta-2.5w | Ta-5.5w | Ta-7.5w | Ta-10w | |

| Impurity Content (≤%) | W | 2.0~3.0 | 4.5~6.5 | 6.5~8.5 | 9.0~11.0 |

| O | 0.0350 | 0.0350 | 0.0350 | 0.0350 | |

| N | 0.0100 | 0.0100 | 0.0100 | 0.0100 | |

| C | 0.0100 | 0.0100 | 0.0100 | 0.0100 | |

| Nb | 0.0050 | 0.0050 | 0.0050 | 0.0050 | |

| Fe | 0.0030 | 0.0030 | 0.0030 | 0.0030 | |

| Si | 0.0020 | 0.0020 | 0.0020 | 0.0020 | |

| Ni | 0.0020 | 0.0020 | 0.0020 | 0.0020 | |

| Cr | 0.0020 | 0.0020 | 0.0020 | 0.0020 | |

| Mo | 0.0010 | 0.0010 | 0.0010 | 0.0010 | |

| Ti | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

| Mn | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

| Cu | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

| Al | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

| Screening | -200 mesh | -200 mesh | -200 mesh | -200 mesh | |

| Oversized material is less than 5%. | |||||

Tantalum Tungsten Alloy Powder Applicable Process

- Metal Injection Molding (MIM)

- Additive Manufacturing (AM)

- Hot Isostatic Pressing (HIP)

- Thermal Spray Coating

Tantalum and Tantalum Alloy Grades

- R05200, unalloyed tantalum, electron-beam furnace vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Tantalum Tungsten Alloy Powder Applications

- Aerospace: Manufacturing high-temperature components like turbine blades and nozzles.

- Electronics: Producing high-performance capacitors and semiconductor components.

- Medical Devices: Creating biocompatible implants, such as bone fixation devices.

- Chemical Industry: Fabricating corrosion-resistant reaction vessels and pipelines.

- 3D Printing: Enabling additive manufacturing of high-precision, heat-resistant complex parts.

- Surface Coatings: Providing wear- and corrosion-resistant protective layers.

Tantalum Tungsten Alloy Powder Packaging

The high-quality tantalum tungsten alloy powder will be carefully handled to prevent damage during storage and transportation. Shanghai Yuepeng offers vacuum-sealed packaging, including 100g/bag, 500g/bag, 1kg/bag, and 25kg/drum, or can offer customized packaging as per specific requirements.

Tantalum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.