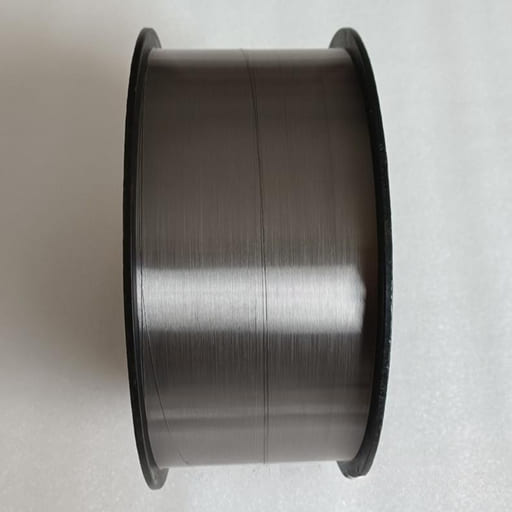

Tantalum Wire

Tantalum Wire

Tantalum Wire is a high-performance material known for its excellent corrosion resistance, high melting point, and superior strength at elevated temperatures. As a leading supplier and manufacturer of premium tantalum products, Shanghai Yuepeng utilizes advanced machining centers to produce high-precision tantalum and tantalum alloy wire products for a wide range of applications.

Tantalum Wire Data Sheet

| Reference: | HMTA0005 |

| Dimensions: | 0.004″ – 0.125″ Dia. x L |

| Standard: | ASTM B365, ASTM F560 (Medical Grade) |

| Material: | R05200, R05400, R05252, R05255, R05240 |

| Purity: | 99%, 99.9%, 99.95%, 99.99%, 99.999% |

| Temper: | Annealed or Unannealed |

Tantalum Wire

Tantalum wire is a high-performance material made from tantalum metal, known for its high melting point, corrosion resistance, and good electrical conductivity. It is widely used in the electronics industry (e.g., capacitor production), medical devices (e.g., implants), and high-temperature industrial applications due to its excellent chemical stability and mechanical properties.

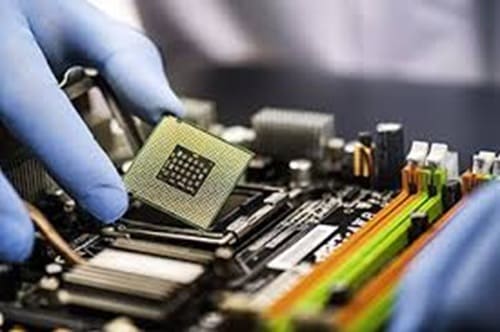

Tantalum Wire Applications

- Tantalum wire can be used to manufacture anode leads for tantalum electrolytic capacitors.

- Tantalum wire can be used to make tantalum yarn or tantalum mesh.

- Tantalum wire can be used to make tantalum capacitors.

- Medical tantalum wire can be used to suture nerves and tendons.

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Tantalum Wire Packaging

The Tantalum Wire is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Tantalum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.