Ti2NbAlC2 MAX Phase Powder

Ti2NbAlC2 MAX Phase Powder

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

Ti2NbAlC2 MAX Phase Powder is a novel ceramic-metallic material known for its excellent conductivity, oxidation resistance, and mechanical stability at elevated temperatures. Its layered structure makes it easier to machine while still maintaining high durability. As a leading supplier and manufacturer of premium MAX Phase Powder products, Shanghai Yuepeng can supply high-quality Ti2NbAlC2 MAX Phase Powder with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Ti2NbAlC2 MAX Phase Powder Data Sheet

| Purity: | ≥99% |

| Size : | 200~500 mesh or customized |

Ti2NbAlC2 MAX Phase Powder Description

Ti2NbAlC2 MAX Phase Powder is a layered ternary carbide material that combines metallic and ceramic properties, making it a promising candidate for advanced structural and functional applications. It exhibits excellent electrical and thermal conductivity, high damage tolerance, and good resistance to thermal shock, while also maintaining the oxidation and corrosion resistance typical of ceramics. The unique crystal structure of Ti2NbAlC2 enables easy machinability compared to conventional ceramics, which significantly broadens its processing flexibility in industrial applications. With its high-temperature stability and outstanding mechanical strength, Ti2NbAlC2 MAX phase is widely investigated for potential use in energy storage systems, high-performance coatings, and electronic devices.

Ti2NbAlC2 MAX Phase Powder Features

- Layered Crystal Structure: Exhibits a unique combination of metallic conductivity and ceramic strength due to its hexagonal layered arrangement.

- High Electrical and Thermal Conductivity: Ensures efficient energy transfer in high-temperature and electronic applications.

- Excellent Oxidation Resistance: Maintains stability and performance even in harsh oxidative environments.

- Good Damage Tolerance: Offers high fracture resistance and thermal shock resistance compared to traditional ceramics.

- Machinability Advantage: Easier to process and shape than conventional ceramics, enabling broader industrial applications.

Ti2NbAlC2 MAX Phase Powder Applications

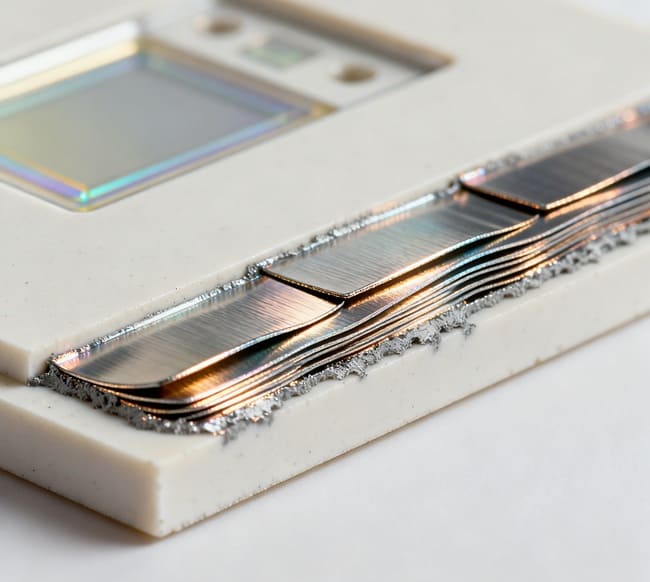

- High-Temperature Structural Materials: Ti2NbAlC2 MAX phase powder maintains mechanical strength and stability under extreme heat, making it suitable for components in aerospace and energy systems.

- Protective Coatings: Its excellent oxidation resistance allows it to be used as a protective coating on metal surfaces, extending the service life of parts exposed to high temperatures and corrosive environments.

- Electrical and Thermal Conductors: With good electrical and thermal conductivity, Ti2NbAlC2 can be used in electronic devices and as conductive or heat-dissipating materials.

- Nuclear Engineering Applications: The material’s excellent radiation tolerance and thermal stability make it a strong candidate for use in nuclear reactors and radiation shielding systems.

- Research and Development of Advanced Ceramics: Ti2NbAlC2 MAX phase powder serves as a valuable material for studying layered ceramic–metal composites and developing next-generation high-performance materials.

- Electrical and Thermal Conductive Parts

- High-Temperature Structural Materials

- Protective Coatings

- Refractory and Composite Materials

- Research and Development of Novel Materials

Download

Get A Quote

We will check and get back to you in 24 hours.