Ti3SiC2 MAX Phase Powder

Ti3SiC2 MAX Phase Powder

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

Ti3SiC2 MAX Phase Powder combines metallic conductivity with ceramic durability, offering high thermal stability, oxidation resistance, and machinability. It is widely used in aerospace, energy, and electronic industries for high-performance applications. As a leading supplier and manufacturer of premium MAX Phase Powder products, Shanghai Yuepeng can supply high-quality Ti3SiC2 MAX Phase Powder with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Ti3SiC2 MAX Phase Powder Data Sheet

| Purity: | ≥98% |

| Size : | 200~500 mesh or customized |

Ti3SiC2 MAX Phase Powder Description

Ti3SiC2 MAX Phase Powder is an advanced ceramic that combines metallic and ceramic characteristics, offering high electrical and thermal conductivity, excellent oxidation resistance, and remarkable damage tolerance. Its layered hexagonal structure provides machinability closer to metals while ensuring stability at elevated temperatures. With strong resistance to thermal shock and fatigue, Ti3SiC2 is well-suited for electrical contacts, high-temperature structural parts, and protective coatings. It is increasingly applied in aerospace, energy, electronics, and advanced manufacturing.

Ti3SiC2 MAX Phase Powder Features

- High Thermal and Electrical Conductivity: Provides metallic-level conductivity, enabling efficient heat and current transfer.

- Excellent Oxidation and Corrosion Resistance: Maintains stability in harsh chemical and high-temperature environments.

- Outstanding Damage Tolerance: Exhibits high fracture toughness and resistance to crack propagation.

- Good Machinability: Can be processed with conventional tools, unlike most ceramics.

- Thermal Shock and Fatigue Resistance: Withstands rapid temperature fluctuations and long-term cyclic loading.

Ti3SiC2 MAX Phase Powder Applications

- High-Temperature Structural Parts: Ti3SiC2 MAX phase powder exhibits excellent thermal stability and mechanical strength, making it suitable for components used in aerospace engines, gas turbines, and high-temperature furnaces.

- Protective Coatings: With outstanding oxidation and wear resistance, Ti3SiC2 is widely used as a protective coating on metals and alloys to enhance durability in harsh chemical or thermal environments.

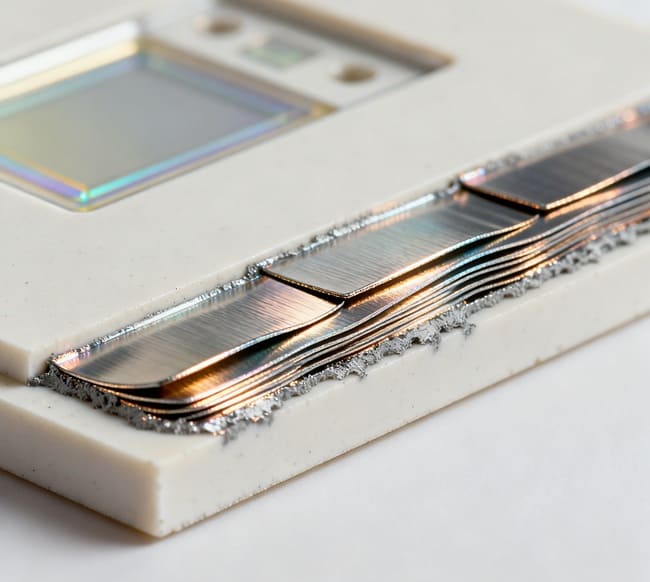

- Electrical and Thermal Conductive Materials: Its metallic-like conductivity and high thermal transfer efficiency make it useful in electronic devices, heat sinks, and energy storage systems.

- Machinable Ceramics: Ti3SiC2 combines ceramic hardness with metal-like machinability, allowing easy shaping into complex forms for industrial parts and cutting tools.

- Nuclear and Energy Applications: The excellent radiation resistance and chemical stability of Ti3SiC2 enable its use in nuclear reactors and other energy-related fields where reliability and safety are critical.

- Electrical and Thermal Conductive Parts

- High-Temperature Structural Materials

- Protective Coatings

- Refractory and Composite Materials

- Research and Development of Novel Materials

Download

Get A Quote

We will check and get back to you in 24 hours.