TiNbCTx MXene Phase Powder

TiNbCTx MXene Phase Powder

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

TiNbCTx MXene Phase Powder is a high-performance 2D material known for its combination of electrical conductivity and surface reactivity. Its layered structure allows functional modification and rapid ion transport, making it suitable for supercapacitors, sensors, and water treatment membranes. It also enhances the strength and durability of composites and ceramics. With stable chemical properties and versatile applications, TiNbCTx is a promising material for advanced electronics and sustainable technologies. As a leading supplier and manufacturer of premium MXene Phase Powder products, Shanghai Yuepeng can supply high-quality TiNbCTx MXene Phase Powder with various specifications and competitive prices, offering customized solutions to meet specific requirements.

TiNbCTx MXene Phase Powder Data Sheet

| Purity: | ≥98% |

| Size : | 2–20 µm, 200–1000 nm or customized |

TiNbCTx MXene Phase Powder Description

TiNbCTx MXene Phase Powder is a cutting-edge 2D material featuring a layered structure with excellent metallic conductivity and tunable surface chemistry. Its design enables easy intercalation and functionalization, making it ideal for energy storage, sensors, and environmental applications. The material also reinforces structural composites and ceramics, improving mechanical strength and multifunctional performance. With high chemical stability and adaptability, it is suitable for advanced coatings and electronic devices. TiNbCTx is emerging as a key material for next-generation smart and sustainable technologies.

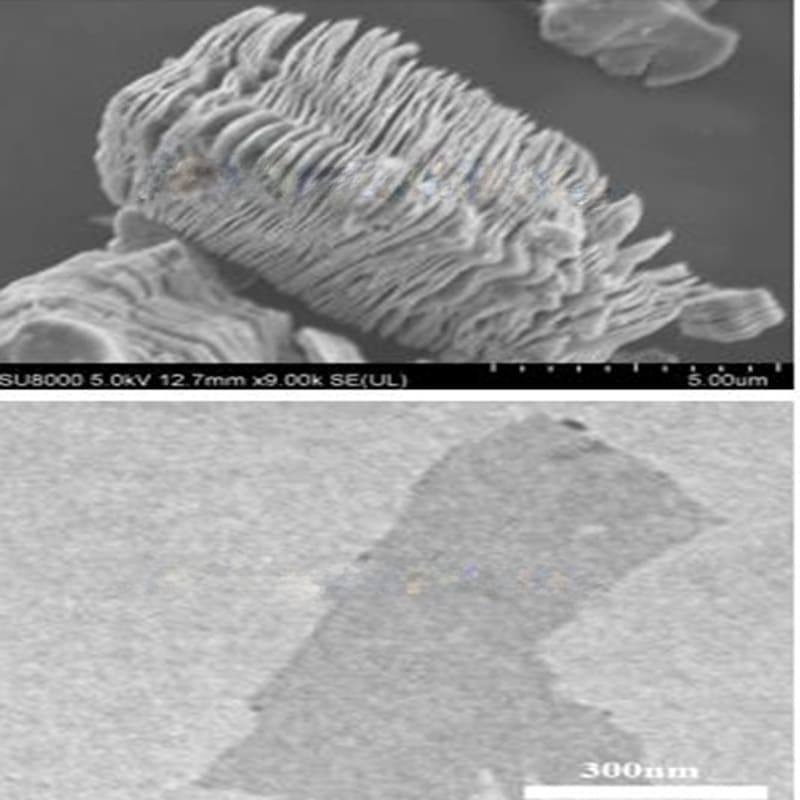

TiNbCTx MXene Phase Powder SEM

TiNbCTx MXene Phase Powder Specifications

| Product | Multilayer TiNbCTx Powder | Single-layer TiNbCTx Powder |

|---|---|---|

| Etching Method | LiF/HCl etching | LiF/HCl etching + intercalation exfoliation |

| Color | Brown | Copper brown |

| Multilayer Size (µm) | 2–20 | / |

| Single-layer Flake Size (nm) | / | 200–1000 |

| Number of Layers | Multilayer | ≤5 layers |

| Concentration (Customizable) | / | / |

| Conductivity (S/cm) | 10–100 | 800 ± 500 |

| Surface Functional Groups | -OH, =O, -F, -Cl | -OH, =O, -F, -Cl |

TiNbCTx MXene Phase Powder Features

- Appearance and Form: Brown powder with uniform particle distribution, ensuring consistent handling and processing in various applications.

- Layered Structure: Exhibits a two-dimensional layered morphology, offering high surface area and tunable interlayer spacing for enhanced material performance.

- Stable Etching Process: Prepared using a LiF/HCl etching system, which improves chemical stability and minimizes defects during synthesis.

- Controllable Flake Size: Flake diameters can be precisely controlled, allowing optimization of electrical, mechanical, and electrochemical properties.

- Enhanced Transition Metal Sites: Niobium atoms are introduced at transition metal positions, enhancing electrochemical activity and conductivity. Recommended storage conditions are under vacuum or in an inert atmosphere to preserve material integrity.

TiNbCTx MXene Phase Powder Applications

- Energy Storage Devices: TiNbCTx MXene Phase Powder is used in lithium-ion and sodium-ion batteries as anode material, offering high electrical conductivity and rapid ion transport for improved charge–discharge performance.

- Supercapacitors: Its large surface area and tunable surface chemistry make TiNbCTx MXene a promising electrode material, providing excellent capacitance and long cycling stability.

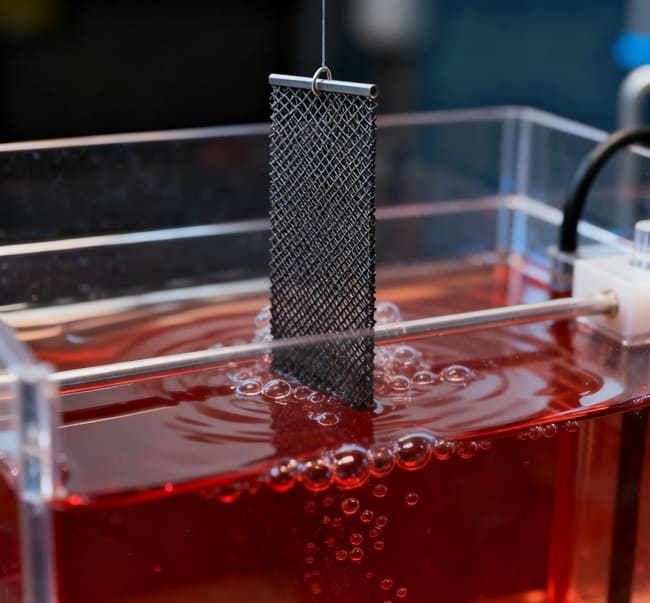

- Electrocatalysis: TiNbCTx acts as an efficient electrocatalyst for hydrogen evolution and oxygen reduction reactions, benefiting from its active surface sites and metallic conductivity.

- Sensors: The material’s high sensitivity to gas and chemical molecules allows it to be applied in environmental monitoring and biosensing technologies.

- EMI Shielding and Conductive Films: TiNbCTx MXene is employed in lightweight electromagnetic interference (EMI) shielding films and conductive coatings due to its high conductivity and mechanical flexibility.

- Catalysis and Hydrogen Production

- Electromagnetic Shielding Materials

- Energy Storage Systems

- Sensing Devices

- Thermal Conductive Coatings

Download

Get A Quote

We will check and get back to you in 24 hours.