(TiZrVNbTa)2AlC MAX Phase Powder

(TiZrVNbTa)2AlC MAX Phase Powder

- Custom sizes and standard sizes in stock

- Quick Lead Time

- Competitive Price

(TiZrVNbTa)2AlC MAX Phase Powder is a high-entropy carbide combining multiple transition metals, offering outstanding thermal stability, oxidation resistance, and mechanical durability. It is used in coatings, structural components, and MXene research. As a leading supplier and manufacturer of premium MAX Phase Powder products, Shanghai Yuepeng can supply high-quality (TiZrVNbTa)2AlC MAX Phase Powder with various specifications and competitive prices, offering customized solutions to meet specific requirements.

(TiZrVNbTa)2AlC MAX Phase Powder Data Sheet

| Purity: | ≥99% |

| Size : | 200~500 mesh or customized |

(TiZrVNbTa)2AlC MAX Phase Powder Description

(TiZrVNbTa)₂AlC MAX Phase Powder is a high-entropy layered carbide material composed of titanium, zirconium, vanadium, niobium, tantalum, aluminum, and carbon. As a member of the MAX phase family, it exhibits the combined characteristics of metals and ceramics, including high electrical and thermal conductivity, oxidation resistance, and excellent machinability. The unique feature of this compound is the high-entropy design at the M-site, where five transition metals coexist, providing enhanced phase stability, mechanical strength, and resistance to extreme environments. This makes (TiZrVNbTa)₂AlC suitable for aerospace structural materials, energy applications, advanced coatings, and as a precursor for high-entropy MXenes with broad potential in catalysis and energy storage.

(TiZrVNbTa)2AlC MAX Phase Powder Features

- High-Entropy Structure: Incorporates five different transition metals (Ti, Zr, V, Nb, Ta) for enhanced phase stability.

- Excellent Thermal Stability: Retains structural integrity under extreme high-temperature conditions.

- Superior Oxidation and Corrosion Resistance: A multi-element composition enhances resistance in harsh environments.

- Mechanical Toughness: Provides high fracture resistance and damage tolerance compared to conventional ceramics.

- MXene Precursor Potential: Can be etched into high-entropy MXenes for use in energy storage and catalysis.

(TiZrVNbTa)2AlC MAX Phase Powder Applications

- High-Temperature Structural Materials: The multi-element composition of (TiZrVNbTa)2AlC provides excellent thermal stability and mechanical strength, making it suitable for aerospace, energy, and industrial applications under extreme temperatures.

- Oxidation-Resistant Coatings: This MAX phase can form a protective oxide layer at elevated temperatures, which enhances oxidation and corrosion resistance for metallic and ceramic substrates.

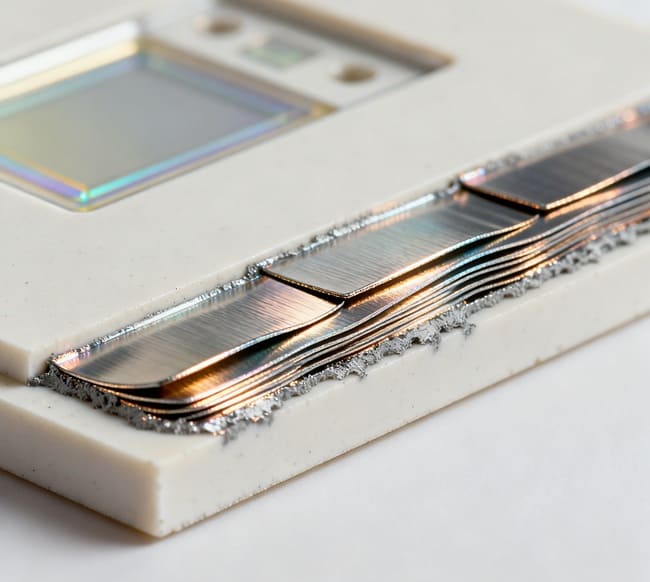

- Electrical and Thermal Conductive Components: With metallic conductivity and good heat transfer ability, (TiZrVNbTa)2AlC is used in electronic devices, heat sinks, and thermal interface materials.

- Reinforcement in High-Entropy Composites: Its high-entropy composition improves the strength, toughness, and stability of composite materials, making it valuable for advanced structural and functional systems.

- Material Research and Development: (TiZrVNbTa)2AlC serves as a model compound for studying high-entropy MAX phases, supporting research into next-generation materials with superior multifunctional properties.

- Electrical and Thermal Conductive Parts

- High-Temperature Structural Materials

- Protective Coatings

- Refractory and Composite Materials

- Research and Development of Novel Materials

Download

Get A Quote

We will check and get back to you in 24 hours.