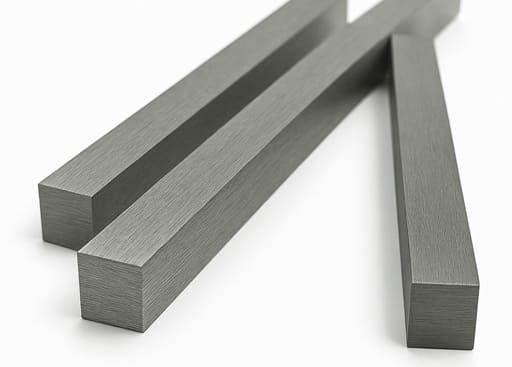

Tungsten Rod/Bar

Tungsten Rod/Bar

Tungsten Rod/Bar is made from high-purity tungsten material through powder metallurgy, molding, sintering, and forging, offering high density, melting point, and hardness. They also have good machinability. As a leading supplier and manufacturer of premium tungsten products, Shanghai Yuepeng utilizes advanced machining centers to produce high-precision tungsten and tungsten alloy rods and bars for a wide range of applications.

Tungsten Rod/Bar Data Sheet

| Reference: | HMWW1114 |

| Dimensions: | Diameter: 0.1″-2″ Length: 10 ft |

| Standard: | ASTM F288 |

| Material: | Tungsten and Tungsten Alloy |

| Purity: | 99%, 99.9%, 99.95%, 99.99%, 99.999% |

| Shape: | Cylinder, Rectangular, or Hexgon |

| Temper: | Annealed or Unannealed |

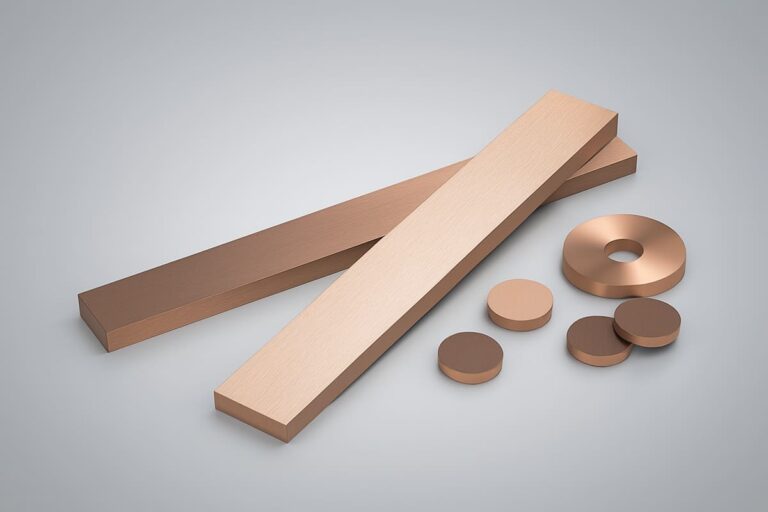

Tungsten Rod and Tungsten Bar

The Tungsten Rod is made from high-purity tungsten metal, known for its high density (approximately 19.3 g/cm³), high melting point (around 3422 °C), and excellent hardness. It is ideal for extreme conditions and is widely used in the manufacture of high-temperature furnaces, arc electrodes, and radiation shielding materials. Shanghai Yuepeng can provide custom sizes, shapes, and compositions to meet specific demands.

Tungsten Rod Tungsten Bar

Tungsten Rod/Bar Material Chemical Composition

| W (>%) | Chemical Content (<%) | |||||||||||

| 99.999 W1 | Fe | Ca | Be | Sn | Al | Ni | Zn | Sb | Pt | K | Ta | Na |

| 0.0001 | 0.00005 | 0.000005 | 0.000005 | 0.00005 | 0.00001 | 0.00005 | 0.00005 | 0.00003 | 0.000005 | 0.0001 | 0.00005 | |

| Cr | Pb | As | Mg | Ti | Bi | Mo | Cd | Cu | Ba | Co | Mn | |

| 0.000005 | 0.00001 | 0.00005 | 0.00005 | 0.000005 | 0.00001 | 0.00001 | 0.000005 | 0.000007 | 0.00001 | 0.000005 | 0.000005 | |

| 99.99 W2 | Fe | Ca | Be | Sn | Al | Ni | Zn | Sb | Pt | K | O | Na |

| 0.0001 | 0.00045 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0005 | 0.0040 | 0.0009 | |

| Cr | Pb | As | Mg | Ti | Bi | Mo | Cd | Cu | Ba | Co | Mn | |

| 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0002 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | |

| 99.95 W3 | Fe | Ca | P | Sn | Al | Ni | N | Sb | Si | O | Pb | As |

| 0.005 | 0.003 | 0.001 | 0.0001 | 0.002 | 0.003 | 0.003 | 0.001 | 0.003 | 0.003 | 0.0001 | 0.002 | |

| Mg | C | Bi | Mo | |||||||||

| 0.002 | 0.005 | 0.0001 | 0.001 | |||||||||

Tungsten Rod/Bar Production Process

- Raw Material: Select high-purity tungsten powder.

- Powder Metallurgy: Mix with binder and compact into a green billet.

- Sintering: High-temperature sintering to remove the binder and increase density.

- Heat Treatment: Anneal to relieve stress and enhance properties.

- Surface Treatment: Clean and polish the surface.

- Cutting & Customization: Cut or customize according to requirements.

Tungsten Rod/Bar Processing Method

- Sintering

- Forging

- Rotary Forging

- Rolling

- Polishing

Tungsten Rod/Bar Surface Treatment

Tungsten rods and bars can undergo various surface treatments to enhance their properties for specific requirements. The most common surface treatments are as follows:

- Polishing

- Grinding

- Coating

- Oxidation

- Electrolytic polish

- Alkaline cleaning

Tungsten Rod/Bar Applications

- High-Temperature Furnaces: Tungsten rods are widely used as heating elements in high-temperature furnaces due to their excellent heat resistance and stability at elevated temperatures.

- Welding Electrodes: Tungsten rods are commonly employed as electrodes and welding tips in various welding processes, including laser welding, electron beam welding, and tungsten inert gas (TIG) welding, thanks to their superior conductivity and durability.

- Electronic Components: Tungsten rods are utilized in the production of electronic components such as filaments, X-ray targets, and resistors, owing to their high melting point and electrical properties.

- Aerospace and Defense: Due to their exceptional strength and wear resistance, tungsten rods are frequently used in aerospace applications, including aircraft engines, rocket propulsion systems, and armor plating.

- Medical Applications: Tungsten rods are also employed in the manufacturing of surgical instruments, implants, and orthopedic devices, as they are non-toxic, non-radioactive, and highly biocompatible.

Tungsten Rod/Bar Packaging

The Tungsten Rod/Bar is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Tungsten Properties

Download

Get A Quote

We will check and get back to you in 24 hours.